To boost efficiency and maximize the performance of your industrial pumps, investing in high-quality pump components is essential. One way to achieve this is by focusing on the speed of the pump.

By optimizing the pump to run at an efficient speed, you can save energy and prolong the lifespan of the pumps.

In addition, pump seals and gaskets play a crucial role in preventing leakage and reducing maintenance needs.

These components provide a tight and secure seal, ensuring fluids are properly contained and preventing any unwanted leaks or spills.

Another important accessory is pump filters and strainers.

These accessories help remove debris or contaminants from the fluid before it enters the pump. This prevents damage and improves overall pump efficiency. Considering the installation of a pump baseplate, it is crucial to also account for the compatibility of pump components to ensure optimal performance.

Click here for more information on: kldpumps.com

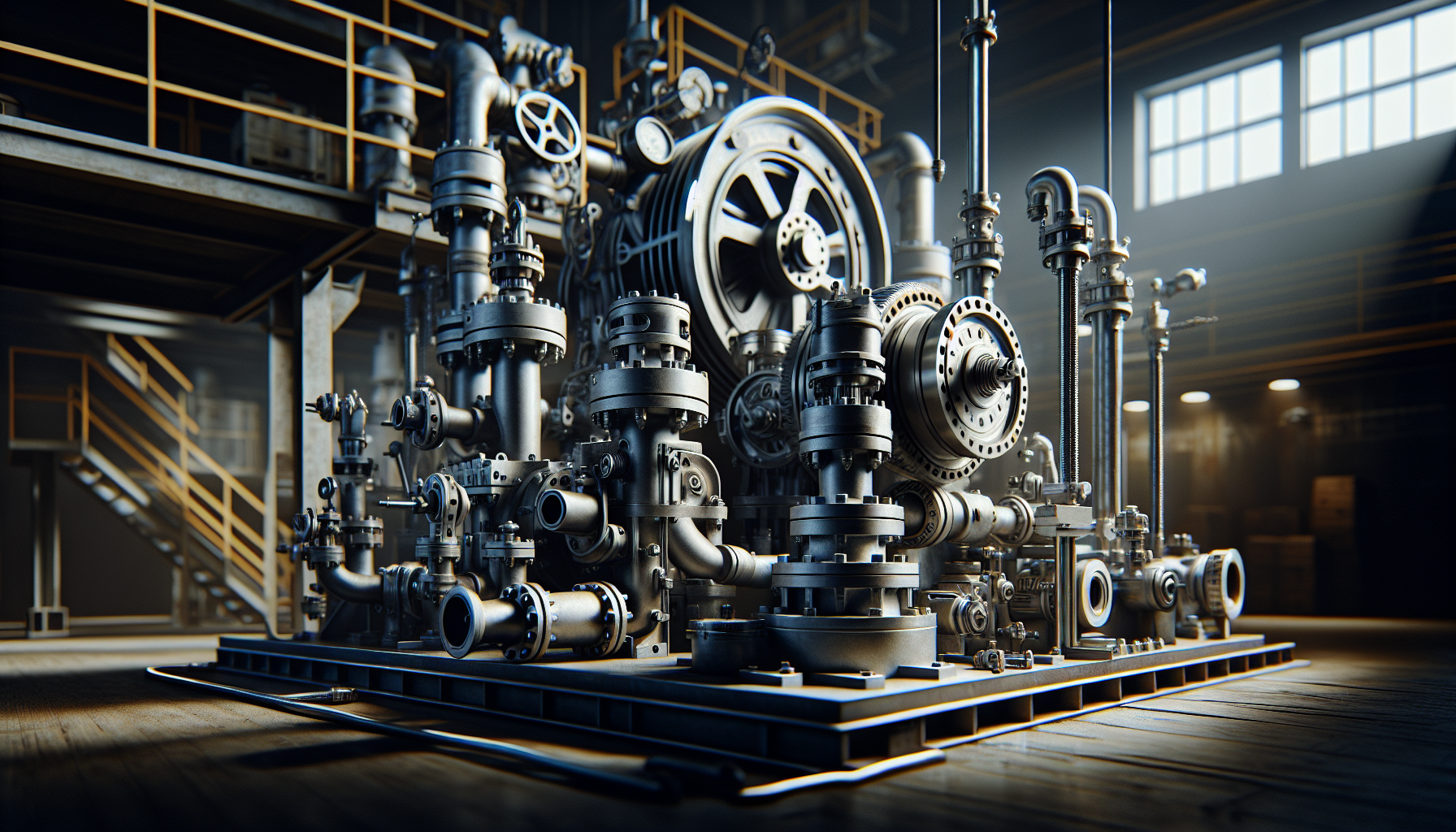

Essential Components of an Industrial Pump System

One vital aspect of an industrial pump system is the addition of pump upgrades. These extra components have the potential to amplify the functionality and performance of the pump.

For instance, impellers, vanes, or diffusers are pump attachments that can optimize the pump’s efficiency by refining fluid flow and boosting pressure.

Variable frequency drives or energy-efficient motors are pump upgrades that can assist in the reduction of energy consumption and operational expenses.

By integrating these pump attachments and upgrades into the system, industries can attain enhanced productivity and superior overall performance from their industrial pump systems.

Choosing the Right Pump Attachments for Your Industrial Needs

When it comes to choosing the right pump options for your industrial needs, pump features and enhancements should be key considerations to keep in mind. Firstly, it is crucial to assess the specific requirements of your industry and determine the type of pump that will be used.

Once this is determined, the material of the attachments becomes important.

To withstand corrosive substances or high-pressure environments, durable materials like stainless steel or cast iron may be necessary.

Another factor to consider is the size and compatibility of the attachments. Choosing the wrong fit could lead to inefficiencies and potential damage.

It is essential to ensure that the attachments are the correct size and compatible with the pump.

It is important to think about the specific tasks that need to be performed with the pump.

Educating yourself with the superior parts and pricing options offered by KLDpumps.com for Wilfley, Krogh, Duro, and Flowserve parts can help you make an informed decision.

Enhancing Performance Upgrades and Options

When it comes to enhancing the performance of industrial pump extras, there are various factors to consider, such as selecting the right pump supplements or exploring pump replacements. It is essential to evaluate the specific needs of the pump system, including flow rate, pressure, and the type of fluid being pumped.

Selecting high-quality materials for pump components, such as stainless steel or corrosion-resistant alloys, can significantly improve the pump’s overall performance and durability.

Another important aspect is the installation of advanced control systems that optimize efficiency and reduce energy consumption.

To further enhance performance, accessories like vibration dampeners and noise reduction systems can be used. Regular maintenance and servicing are crucial for ensuring optimal performance and identifying any potential issues or wear.

By focusing on these aspects, industrial pump supplements can be upgraded and optimized to maximize efficiency.

Exploring Features and Functionalities of Pump Peripherals

When it comes to exploring the features and functionalities of pump peripherals, one area that deserves attention is pump extensions. These extensions are crucial in extending the reach and capabilities of industrial pumps by adding extra length to the suction or discharge pipe.

By using pump extensions, users can effortlessly access hard-to-reach areas or accommodate specific installation requirements.

This level of flexibility greatly enhances the versatility and effectiveness of pump systems, ensuring they can efficiently cater to various applications.

At KLD Pumps, we are dedicated to educating our readers about the superior parts and pricing we offer for renowned brands like Wilfley, Krogh, Duro, and Flowserve.

Facts about Pump Extensions

- Pump extensions extend the reach and capabilities of industrial pumps.

- They add extra length to the suction or discharge pipe.

- Pump extensions allow users to access hard-to-reach areas effortlessly.

- They accommodate specific installation requirements, enhancing the flexibility of pump systems.

Importance of High-Quality Pump Materials in Applications

High-quality pump materials are crucial for ensuring the efficiency and longevity of various industrial applications, especially for pump equipment and devices. These materials are specially designed to withstand the harsh conditions and demands of pumping systems, which in turn ensures reliable operation and minimizes downtime.

One significant benefit of using high-quality pump materials is their resistance to corrosion and wear.

Industrial pumps often come into contact with corrosive fluids and abrasive particles, both of which can cause damage and reduce performance over time.

To combat this, materials like stainless steel, bronze, or specialized alloys are utilized. These materials possess excellent corrosion and erosion resistance, guaranteeing long-term durability and reliability. Another critical factor to consider is the compatibility of pump equipment, as it directly affects the overall performance and efficiency of the system.

Tools and Equipment for Maintaining Industrial Pumps

When it comes to maintaining industrial pumps, having the right pump gear and supplies is essential. At KLDpumps.com, we understand the importance of quality parts and affordable pricing for pumps like Wilfley, Krogh, Duro, and Flowserve.

Our superior parts ensure that maintenance technicians can easily check and replace worn-out components such as seals, impellers, and bearings.

By doing so, unexpected breakdowns can be prevented, and the lifespan of the pumps can be extended.

Our tools and equipment also facilitate efficient repair and troubleshooting, minimizing downtime and maximizing pump efficiency. We offer proper pump fittings, accessories, and personal protective equipment to ensure safe installation, operation, and maintenance of industrial pumps.

Industrial Pump Maintenance

- Quality parts and affordable pricing are crucial for maintaining industrial pumps.

- Superior parts like seals, impellers, and bearings help prevent unexpected breakdowns and extend the lifespan of pumps.

- Tools and equipment provided by KLDpumps.com facilitate efficient repair and troubleshooting, minimizing downtime and maximizing pump efficiency.

- KLDpumps.com also offers proper pump fittings, accessories, and personal protective equipment to ensure safe installation, operation, and maintenance of industrial pumps.

Extending Lifespan with Proper Replacements and Extensions

Maintenance routines are an essential aspect of determining when replacements or extensions are necessary for industrial equipment, particularly pump hardware and instruments. Regular inspections and assessments can help identify signs of wear and tear, such as decreased performance, unusual noises, or leaks.

These indicators suggest that specific parts may require replacement or extension to ensure optimal functioning.

Manufacturers typically offer precise guidelines for installing replacements and extensions, which should be followed meticulously to avoid complications or future problems.

By adhering to these maintenance routines and guidelines, the lifespan of industrial equipment can be significantly prolonged, resulting in cost savings and enhanced productivity.

Maximizing Efficiency with Innovative Pump Gadgets

In today’s fast-paced industrial world, the need for businesses to maximize efficiency and stay competitive is vital, especially when it comes to implementing advanced pump systems. To achieve this goal, one area where significant improvements can be made is with the utilization of innovative pump mechanisms.

These cutting-edge devices are specifically designed to enhance the performance of pump systems, and pump units, resulting in increased productivity and cost savings.

By incorporating these innovative devices into their operations, businesses can experience smoother operation, minimal downtime, and improved overall efficiency.

KLDpumps.com offers a wide range of superior parts and competitive pricing for renowned brands like Wilfley, Krogh, Duro, and Flowserve. From advanced impellers, seals, couplings to bearings, these pump accessories from KLDpumps.com will optimize pump functionality and achieve maximum efficiency.

Benefits of Utilizing Innovative Pump Mechanisms

- Enhanced performance of pump systems and pump units.

- Increased productivity and cost savings.

- Smoother operation and minimal downtime.

- Improved overall efficiency.

Powerful Pump Repair Parts: Fix It Fast

Pump Spare Parts: Your Essential Guide