Sand casting aftermarket parts are essential for improving the performance of your vehicle. These components, usually made from aluminum or steel, are designed to withstand tough conditions and deliver optimal results.

Known for their durability and precise manufacturing process, sand-casting aftermarket parts are an excellent choice for boosting your vehicle’s horsepower, fuel efficiency, and handling.

They also offer a wide range of customization options, allowing you to personalize your vehicle to suit your specific needs and preferences.

When searching for sand-casting aftermarket parts, it is advisable to seek guidance from industry professionals to ensure you choose the right components for your vehicle. By utilizing these high-quality parts, you can unlock your vehicle’s maximum potential. If you’re looking for superior parts and pricing for Wilfley, Krogh, Duro, and Flowserve sand casting aftermarket components, our company has the solution for you.

Click here to learn more about KLD Pumps

Advantages of Using Aftermarket Parts for Sand Casting

Whether you need aftermarket replacements or are looking for a general upgrade, aftermarket parts offer a variety of choices to suit your needs.

Moreover, aftermarket replacements for sand casting provide quick and easy replacements.

If a component breaks or wears out, you can easily find and replace the specific part without having to wait for OEM replacements.

This minimizes downtime and allows for seamless operations, improving overall productivity.

Additionally, aftermarket parts for sand casting often come with warranties and customer support. This ensures that you have peace of mind and assistance in case any issues arise.

With dependable customer service, you can rely on prompt solutions and guidance for any concerns you may encounter. Sand casting upgrades utilizing aftermarket replacements offer enhanced performance and durability.

Choosing the Right Aftermarket Components for Sand Casting

Sand casting is a widely used method in the manufacturing industry, and choosing the right aftermarket options for this process is crucial. With a variety of sand casting options available, you can select the best sand casting solutions for your specific casting needs.

Whether you need replacements or upgrades, components offer flexibility and convenience to keep your operations running smoothly.

These aftermarket solutions often come with warranties and customer support, ensuring assistance throughout the casting process.

When it comes to performance and durability, selecting the right components is vital for achieving optimal results in sand casting. To find superior parts and competitive pricing for brands like Wilfley, Krogh, Duro, and Flowserve, visit KLDpumps.com

| Sand Casting Options | Aftermarket Solutions | Components |

|---|---|---|

| Wide variety available | Offer flexibility and convenience | Vital for optimal results |

| Choose the best for specific needs | Come with warranties and customer support | Find superior parts for brands like Wilfley, Krogh, Duro, and Flowserve |

The Importance of Quality in Aftermarket Replacements for Sand-Casting

When it comes to aftermarket replacements for sand-casting equipment, it is important to prioritize quality. High-quality replacements ensure that the repaired or replaced parts will function effectively and meet the original specifications.

This is especially crucial in industries where precision and reliability are paramount, such as the automotive, aerospace, and heavy machinery sectors.

One key factor in ensuring quality replacements is choosing the right materials.

These materials should be of equal or higher quality compared to the original parts. They should provide the necessary strength, durability, and resistance to wear and tear.

The manufacturing process should employ advanced techniques and technologies to ensure accuracy and consistency. To achieve the highest quality standards, it is vital to partner with an experienced supplier of sand casting equipment.

Exploring the Range of Aftermarket Upgrades for Sand-Casting

When exploring the range of aftermarket upgrades for sand-casting, it is crucial to consider the specific needs of the sand-casting systems. This includes taking into account the type of sand-casting materials and aftermarket materials that will optimize the process and enhance the quality of the final product.

Selecting the right sand-casting systems and aftermarket systems, as well as utilizing sand-casting kits and aftermarket kits, can greatly impact the overall efficiency and success of the casting process.

By incorporating these upgrades, manufacturers can achieve improved precision, reliability, and durability in their sand-casted products.

If you are looking for superior parts and pricing for Wilfley, Krogh, Duro, and Flowserve parts, be sure to check out KLDpumps.com. They offer top-of-the-line sand-casting systems and aftermarket kits.

Essential Tools and Equipment for Aftermarket Sand-Casting Parts

When it comes to sand-casting, choosing the right tools and equipment is crucial for achieving excellent results in the aftermarket industry, whether it be sand-casting manufacturers or aftermarket retailers. Whether you are a sand casting manufacturer, distributor, or retailer, having the appropriate tools can make a significant difference.

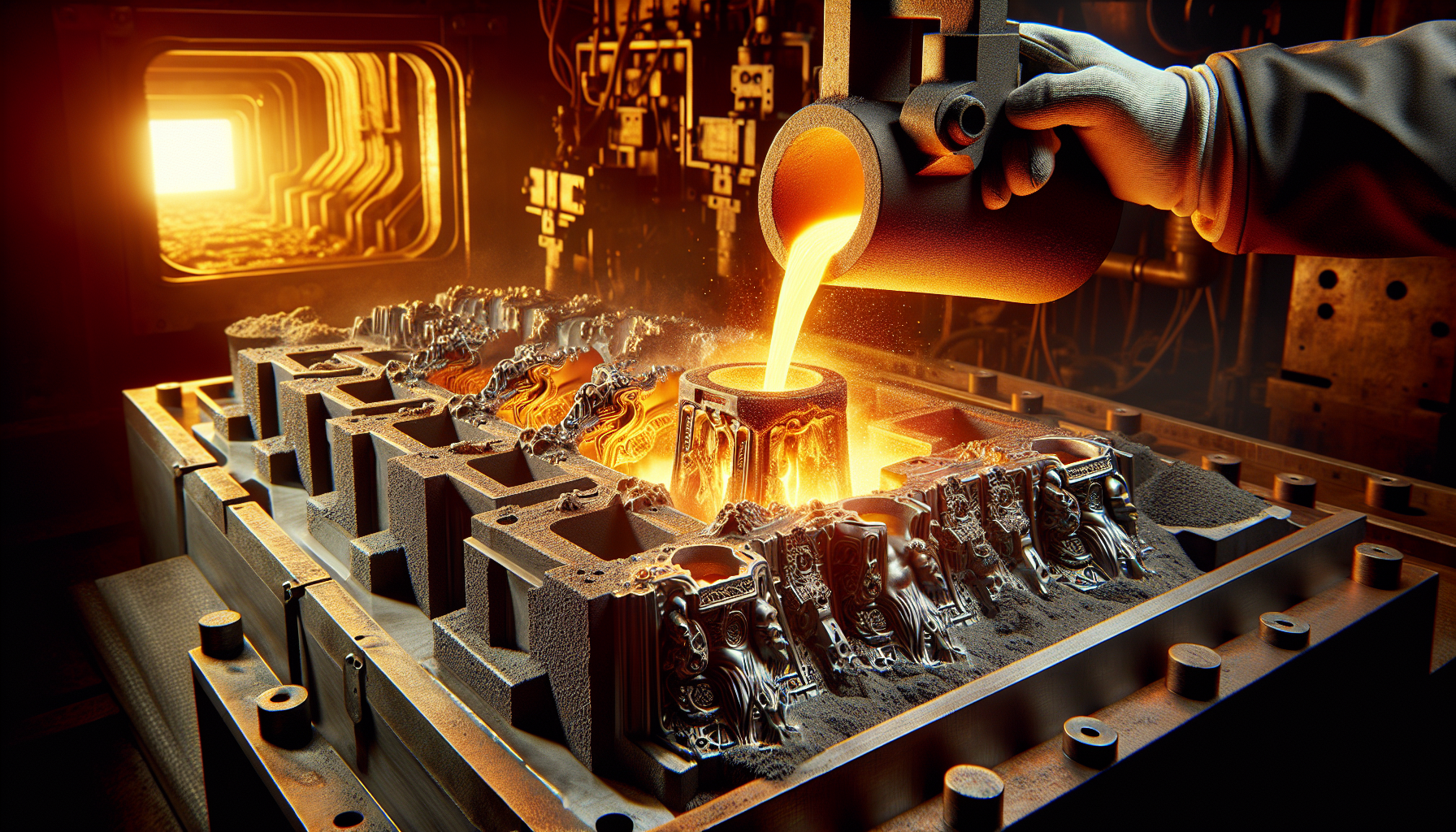

Alongside the crucible, mold, pattern, and venting and gating tools, another essential item to consider is the sand-casting furnace.

The furnace is responsible for melting the metal that will be poured into the mold, ensuring precise temperature control and consistent outcomes.

It is important to invest in a top-notch furnace to ensure the production of high-quality aftermarket parts in sand-casting.

Top Considerations When Selecting Aftermarket Suppliers for Sand Casting Materials

When it comes to choosing aftermarket wholesalers for sand-casting materials, sand-casting buyers should consider several crucial factors. Firstly, the quality of the materials provided by the supplier is of utmost importance.

Sand casting requires durable, heat-resistant materials that can produce high-quality castings.

Therefore, it is essential to select a supplier that offers top-notch materials.

Expertise and experience in the field of sand casting are important considerations. Working with a supplier who thoroughly understands the sand casting process and can provide expert guidance is crucial.

This ensures that the materials supplied are suitable for the specific sand casting requirements.

Reliability and the ability to meet deadlines are vital factors to consider as well.

Timely delivery of materials is crucial for sand-casting projects, so selecting a supplier with a proven track record in meeting deadlines is essential. It is important to balance cost with quality, expertise, and the needs of sand casting buyers and sellers.

| Crucial Factors | Importance |

|---|---|

| Quality of Materials | Utmost |

| Expertise and Experience | Important |

| Reliability and Meeting Deadlines | Vital |

| Cost-Effectiveness | Important |

Enhancing the Performance of Sand-Casting Systems with Aftermarket Solutions

Aftermarket solutions play a crucial role in improving the performance of sand-casting dealers, aftermarket dealers, sand-casting suppliers, and aftermarket suppliers, as these vendors offer a wide range of products and services to address the specific challenges faced by foundries. These solutions are designed to enhance the quality and consistency of sand molds and optimize the casting process.

They promote environmental sustainability.

Foundries can reduce defects, improve yield, increase productivity, and minimize waste generation by utilizing advanced sand additives, binders, automated pouring systems, temperature control devices, and mold coating solutions.

Choosing the right aftermarket vendors is essential to ensuring the success of sand-casting projects.

Common Challenges and Solutions in Sourcing Aftermarket Sand-Casting Accessories

Sourcing aftermarket sand-casting accessories can be a complex process for manufacturers, especially when dealing with sand-casting exporters or aftermarket importers. Trustworthy suppliers who can meet specific requirements are hard to find, especially for older or less popular equipment models.

Solutions exist.

Building strong relationships with reputable exporters, traders, and importers specializing in aftermarket accessories is key.

By collaborating with reliable suppliers and utilizing KLDpumps.com, businesses can overcome challenges in sourcing aftermarket sand-casting accessories.

| Key Suppliers | Specialization | Product Range | Quality Assurance |

|---|---|---|---|

| Exporter A | Aftermarket accessories | Wide range of sand-casting parts | Stringent quality control measures |

| Trader B | Aftermarket accessories | Parts for older and less popular equipment models | High-quality parts with competitive pricing |

| Importer C | Aftermarket accessories | Parts for Wilfley, Krogh, Duro, and Flowserve | Superior parts and pricing |