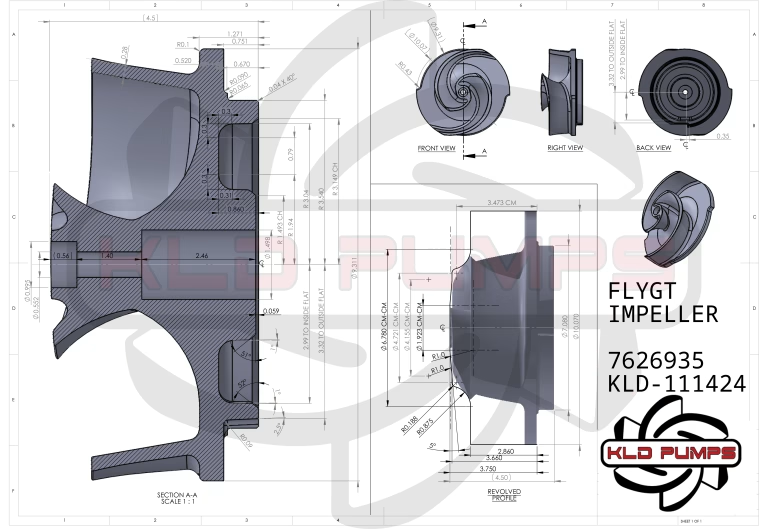

Flygt 3153 Pump Upgrade: Aftermarket Impeller 7626935

Elevate the performance and reliability of your Flygt 3153 series pump with a dual-action upgrade engineered for the harsh realities of modern fluid handling. Move beyond the inherent limitations of standard OEM parts and equip your pump with an impeller that is purpose-built to conquer abrasion, corrosion, and chronic clogging simultaneously.

Executive Summary: Why KLD’s 7626935 is Superior

Advanced Metallurgy

Engineered from premium CD4MCuN Duplex Stainless Steel, our impeller provides superior resistance to both chemical corrosion and abrasive wear, drastically extending service life in aggressive fluids compared to standard high-chrome iron.

Clog-Free Hydraulic Design

Featuring a proven self-cleaning design inspired by N-technology, our impeller uses swept-back leading edges to actively repel fibrous materials and solids, ensuring reliable, clog-free operation and sustained hydraulic efficiency.

Lower Total Cost

A more durable, efficient, and reliable impeller means fewer maintenance cycles, the elimination of unscheduled downtime, and reduced energy consumption. This translates to a significantly lower total cost of ownership (TCO).

In-Depth Technical Analysis

Part 1: The Material Upgrade (CD4MCuN vs. High-Chrome Iron)

The standard OEM impeller for the Flygt 7626935 is typically cast from high-chromium white iron (per ASTM A532). While possessing high hardness, this material represents a significant engineering compromise. In the complex environments of municipal wastewater, industrial sludge, and chemical effluent, its weaknesses become critical liabilities. High-chrome iron is inherently brittle, making it highly susceptible to catastrophic fracturing from impact with tramp material. Furthermore, its electrochemical properties offer poor resistance to corrosion from chlorides, sulfides, and varying pH levels. This corrosive attack initiates pitting and weakens the material’s surface, which dramatically accelerates abrasive wear and leads to premature, costly failure.

Our aftermarket 7626935 impeller is a full metallurgical upgrade, manufactured from CD4MCuN Duplex Stainless Steel (ASTM A890 1B). This advanced alloy’s balanced austenite-ferrite microstructure provides the “best of both worlds”: the superior corrosion resistance and high toughness of austenitic steel, combined with the high strength and stress corrosion cracking resistance of ferritic steel. The inclusion of Molybdenum and Nitrogen significantly boosts its resistance to pitting (high PREN value), while Copper enhances its performance in acidic environments. The result is a tough, ductile component that is exceptionally resistant to the pitting, crevice corrosion, and impact damage that destroys standard iron impellers.

Material Specification Showdown

| Property | Standard OEM High-Chrome Iron (ASTM A532) | KLD Pumps CD4MCuN (ASTM A890 1B) |

|---|---|---|

| Primary Wear Resistance | Sliding Abrasion | Synergistic Corrosion & Abrasion |

| Toughness (Impact Resistance) | Low (Brittle) | High (Ductile) |

| Common Failure Mode | Fracturing, Pitting, Accelerated Wear | Gradual, predictable wear over an extended service life |

| Repairability | Poor (Difficult to weld) | Good (Weldable with proper procedure) |

Part 2: The Hydraulic Upgrade (Self-Cleaning Design)

Modern wastewater is increasingly difficult to pump, often containing high concentrations of fibrous materials, “flushable” wipes, plastics, and other solids that clog traditional impellers, leading to costly downtime and maintenance. Our aftermarket 7626935 impeller incorporates proven self-cleaning N-technology principles to eliminate this chronic problem and ensure sustained performance.

- Swept-Back Leading Edges: Unlike conventional radial vanes that can snag and capture fibrous material, our impeller’s leading edges are sharply swept back. This innovative geometry creates a hydraulic action that actively guides solids and rags away from the impeller’s center and pushes them through the volute, preventing the buildup and entanglement that leads to clogs.

- Relief Groove: A complementary, patented-style relief groove in the pump volute creates a continuous, self-clearing flow path. This synergy between the impeller and the casing ensures that any solids that approach the periphery are immediately and powerfully transported out with the main flow, maintaining optimal hydraulic efficiency and preventing internal recirculation of abrasive materials.

This intelligent, clog-resistant design delivers sustained high efficiency over the pump’s entire operational curve. This not only prevents nuisance call-outs for de-ragging but also reduces energy consumption over the life of the pump, delivering significant operational savings.

Ideal Applications for This Dual Upgrade

This impeller is the definitive performance upgrade for Flygt 3153 pumps operating in the most demanding sectors, especially:

- Municipal Wastewater Lift Stations: Eliminate chronic clogging issues from modern residential and industrial waste streams (e.g., rags, wipes, and plastics).

- Industrial Effluent & Sludge: Reliably handle corrosive and abrasive solids from manufacturing processes, food production, and chemical plants.

- Pulp and Paper Processing: Manage fibrous slurries, black liquor, and other challenging fluids without the constant threat of blockages.

- Mining Dewatering: Withstand both corrosive acid mine drainage (AMD) and highly abrasive solids with unmatched durability and reliability.

Stop reacting to pump failures and start investing in reliability. Upgrade to the KLD Pumps aftermarket impeller and fortify your critical equipment against its toughest challenges. Contact us today for a quote.

Technical Resources & Further Reading

The engineering principles behind self-cleaning hydraulic designs are well-established in the industry. For those interested in a deeper technical dive, the following resources provide excellent background information: