Superior Aftermarket Parts for Flygt Submersible Pumps

Stop replacing. Start upgrading. KLD Pumps provides premium, American-made aftermarket parts for a wide range of Flygt submersible pumps. We go beyond simple OEM replication by applying advanced metallurgy and precision engineering to create components that deliver longer service life, greater reliability, and a lower total cost of ownership in the most demanding industrial environments.

The KLD Engineering Advantage

Advanced Metallurgy

- Utilizes superior alloys like CD4MCuN Duplex Stainless Steel.

- Overcomes corrosion and wear limitations of standard high-chrome iron.

- Withstands chemical attack without sacrificing hardness.

Precision Manufacturing

- Employs advanced 3D scanning for perfect component replication.

- Uses state-of-the-art CNC machining for exacting tolerances.

- Ensures flawless fit, hydraulic performance, and efficiency.

Increased ROI

- Engineered for longevity to reduce maintenance cycles.

- Minimizes costly, unscheduled operational downtime.

- Shifts your strategy from reactive repair to proactive reliability.

Engineered Solutions for Common Flygt Failure Points

We analyze common OEM component failures and engineer targeted upgrades. See how our parts solve the problems that lead to downtime.

| Component | Common OEM Failure Points | The KLD Engineered Solution |

|---|---|---|

| Impellers |

|

|

| Casings (Volutes) |

|

|

| Wear Rings |

|

|

| Shafts |

|

|

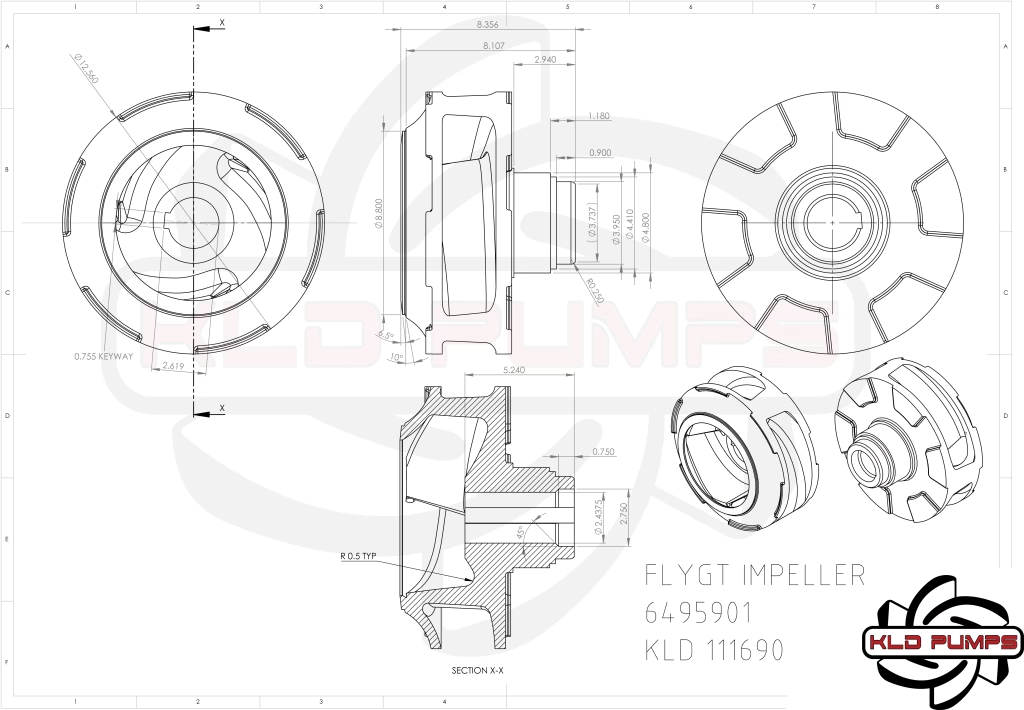

Product Spotlight: Flygt Impeller 6495901 Upgrade

Specifically engineered for the workhorse Flygt 2600 series dewatering pumps (e.g., Flygt 2660), the KLD aftermarket 6495901 impeller is a direct upgrade for high-wear applications. Found in the toughest dewatering jobs in mining, tunneling, and construction, this impeller often fails when faced with both corrosive water and abrasive solids. Our version is the definitive solution.

| Feature | Standard OEM Impeller (6495901) | The KLD Upgrade (6495901) |

|---|---|---|

| Material | High-Chrome White Iron | CD4MCuN Duplex Stainless Steel |

| Primary Application | Abrasive slurry pumping | Pumping abrasive and corrosive slurries |

| Key Weakness | Brittle; poor resistance to chemical attack | Engineered to eliminate these weaknesses |

| KLD Advantage | Good abrasion resistance in neutral fluids | Superior toughness and extreme corrosion resistance |

| Result for Your Operation | Frequent replacements in complex environments | Longer service life, less downtime, lower costs |

Engineered for Your Industry’s Toughest Challenges

KLD parts are engineered to provide enhanced reliability where it matters most:

- Municipal Water & Wastewater:

- Challenge: Abrasive grit, corrosive chemicals, and stringy solids.

- Solution: Tough, corrosion-resistant materials that prevent clogging and premature wear in lift stations and treatment plants.

- Mining & Construction:

- Challenge: Acid mine drainage, heavy slurries, and high solids content.

- Solution: Materials that resist brittle fracture and withstand both low-pH corrosion and extreme abrasion.

- Pulp & Paper:

- Challenge: Handling chemically aggressive black liquor and abrasive recovery fluids.

- Solution: Advanced alloys that provide a cost-effective, long-term alternative to exotic and expensive materials.

- Industrial Effluent Treatment:

- Challenge: A wide, unpredictable range of aggressive chemical waste streams.

- Solution: Versatile duplex stainless steel components that offer reliable performance across diverse applications.

Ready to Upgrade Your Flygt Pumps?

Contact the KLD Pumps team today to discuss your specific application. Let us show you how our engineered aftermarket parts can increase the reliability and performance of your critical equipment.

Request a Quote