Lost wax casting, also known as investment casting, offers numerous advantages over sand casting including the ability to produce complex and detailed parts with excellent dimensional accuracy. This makes it the preferred method for applications that require intricate designs or tight tolerances.

Investment casting offers a wide range of material choices, including both ferrous and non-ferrous metals.

On the other hand, sand casting is a more cost-effective method suitable for producing large and simple parts.

It is also better suited for casting materials with high melting points, such as steel or iron. Sand casting has limitations when it comes to dimensional accuracy and surface finish compared to investment casting.

Investment casting and sand casting are two distinct casting processes used in the manufacturing industry. While investment casting offers high accuracy and intricate details, sand casting is more cost-effective for larger and simpler parts. To learn more about superior parts and pricing options for brands like Wilfley, Krogh, Duro, consider researching the investment casting process, as it offers several advantages over sand casting and other metal casting techniques.

Click here to learn more about KLD Pumps

Difference between investment casting and sand casting

When comparing investment casting to sand casting, one crucial factor to consider is the cost difference between the two processes. Investment casting tends to be more expensive due to the intricate process involved.

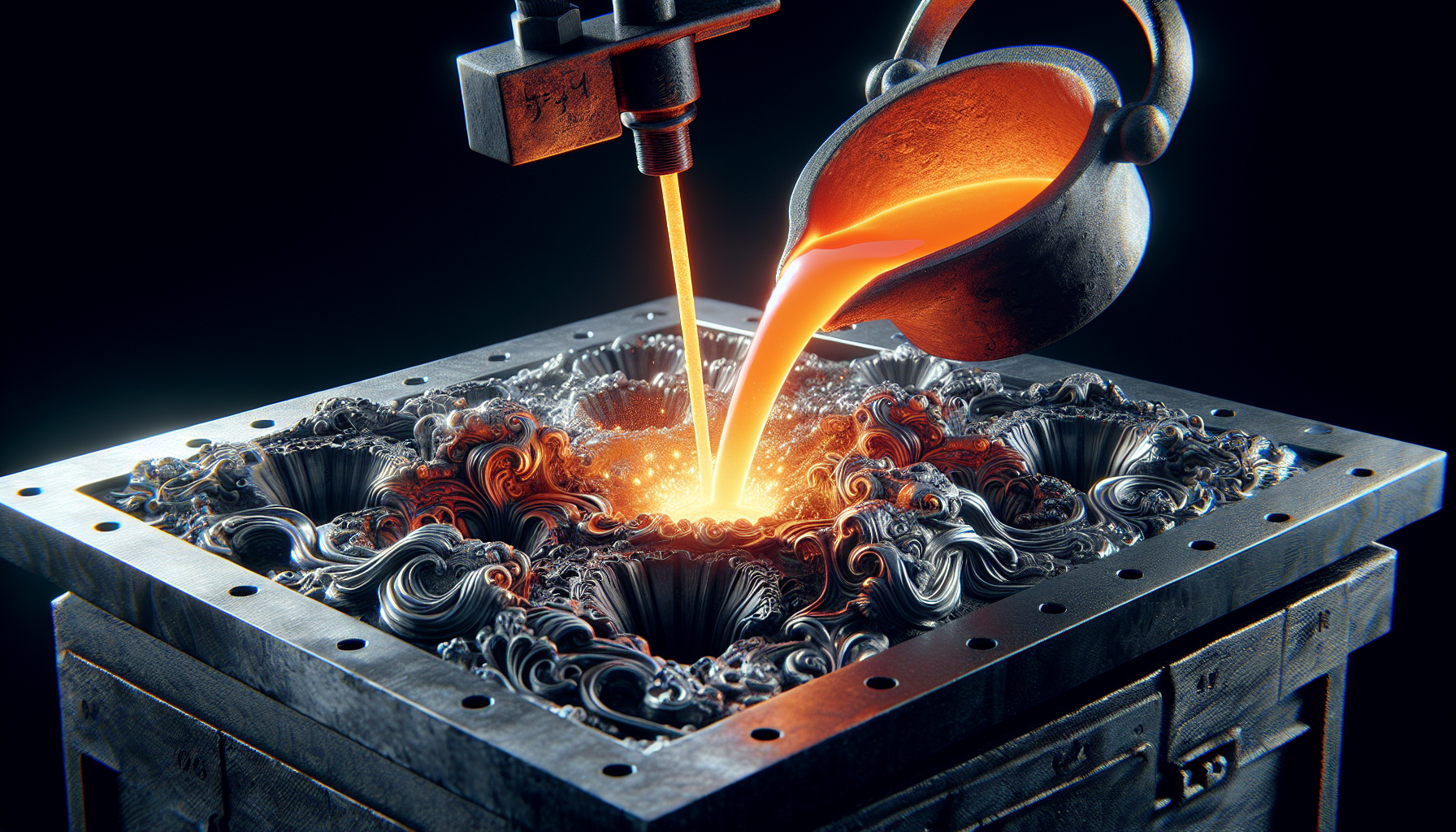

This process includes creating wax patterns, coating them with ceramic, and breaking away the shell.

On the other hand, sand casting is a more cost-effective method as it uses readily available materials like sand and a binder.

The lower cost of sand casting comes at the expense of precision and surface finish. Therefore, while investment casting may be pricier, it offers superior dimensional accuracy and a smoother surface finish. This makes it worth the investment for intricate and precise components due to its superior surface finish and tighter tolerances.

Cost-effectiveness of investment casting and sand casting

Investment casting and sand casting are two popular methods of metal casting, each with its own cost-effectiveness depending on specific requirements such as flexibility, complexity, design, quality, weight, and material. Investment casting offers greater flexibility in creating intricate and complex shapes with high precision.

It comes with higher upfront costs due to the need for wax patterns and ceramic molds.

On the other hand, sand casting provides a more cost-effective option, especially for larger and heavier parts.

While it may not offer the same design intricacy and precision as investment casting, it is a suitable choice for those working with budget constraints. At KLD Pumps, we provide superior parts and pricing for popular brands like Wilfley, Krogh, Duro, and Flowserve, ensuring quality products at competitive prices.

Investment Casting and Sand Casting

- Investment casting allows for the creation of intricate and complex shapes with high precision.

- Sand casting is a more cost-effective option, especially for larger and heavier parts.

- Investment casting requires wax patterns and ceramic molds, leading to higher upfront costs.

- Sand casting may not offer the same design intricacy and precision as investment casting.

Strength comparison of investment casting and sand casting

Effective compared to investment casting, as it requires less expensive materials and equipment, sand casting offers a more cost-effective solution for production in the manufacturing industry. The precision and strength advantages of investment casting make it more suitable for applications that require high-quality and complex castings.

Overall, when considering the strong comparison of investment casting and sand casting, investment casting emerges as the superior option due to its ability to produce precise, detailed, and strong castings with improved mechanical properties.

Tolerance levels in investment casting and sand casting

In addition to their differences in precision and complexity, tolerance levels play a significant role in distinguishing investment casting from sand casting in terms of efficiency. Tolerance refers to the acceptable variation in dimensions and is crucial in ensuring the final castings meet the required specifications.

Investment casting generally demands tighter tolerance levels compared to sand casting.

This is because investment casting utilizes a wax pattern coated with a ceramic shell, allowing for intricate details and complex geometries.

In contrast, sand casting offers larger tolerance ranges due to its forgiving nature, making it suitable for producing larger and less intricate components. Factors such as part complexity, casting material, and application requirements should be considered when determining appropriate tolerance levels.

To explore superior parts and pricing for Wilfley, Krogh, Duro, Flowserve, visit KLD Pumps.

Surface finish options in investment casting and sand casting

When it comes to surface finish options in investment casting and sand casting, manufacturers have a range of choices to consider, including investment casting vs sand casting features and benefits. These options not only affect the final appearance of the cast parts but also their quality and performance.

In investment casting, one popular choice is a smooth finish, which gives the cast parts a polished and refined look.

Another option is a textured finish, which adds a unique pattern or texture to enhance the aesthetic appeal.

Additionally, investment casting allows for various surface treatments like plating, painting, and powder coating, which provide additional protection from corrosion.

In sand casting, the texture of the sand mold used directly affects the surface finish. Coarser sand grains result in a rougher finish, which may impact the overall quality and cost of investment casting versus sand casting manufacturing.

Role of tooling in investment casting and sand casting

In the realm of investment casting and sand casting, the role of tooling is paramount for the advancements and future of both technologies. Tooling serves as the foundation for these casting processes, determining the shape, precision, and overall quality of the final castings.

When it comes to investment casting, tooling takes the form of molds or patterns that are meticulously crafted to achieve the desired shape of the end product.

These molds are often made from easily meltable materials like wax and are produced using cutting-edge techniques such as 3D printing or CNC machining.

These techniques ensure an accurate replication of the intended design.

The versatility of tooling in investment casting allows for its application in various industries, from aerospace to automotive and medical.

On the other hand, in sand casting, tooling plays a vital role in creating the molds that contain the molten metal during the casting process. These molds are essential for achieving investment casting vs sand casting technology.

Tooling in Investment Casting and Sand Casting

- Tooling is crucial in investment casting and sand casting as it determines the shape, precision, and overall quality of the final castings.

- In investment casting, tooling takes the form of meticulously crafted molds or patterns made from materials like wax, ensuring an accurate replication of the intended design.

- Tooling in investment casting finds applications in various industries, including aerospace, automotive, and medical.

- In sand casting, tooling plays a vital role in creating molds that contain the molten metal during the casting process, enabling the use of investment casting vs sand casting technology.

Lead time comparison of investment casting and sand casting

When comparing the lead time of investment casting and sand casting, one important aspect to consider is the level of intricacy and complexity achievable with each process, as this impacts their respective applications and uses. Investment casting enables the creation of highly detailed and intricate parts, which makes it an ideal choice for designs or components with tight tolerances.

On the other hand, sand casting is more suitable for simpler shapes and larger parts.

Investment casting generally requires a longer lead time due to the multiple steps involved, such as creating the wax pattern and coating it with a ceramic shell.

It is worth noting that the lead time can vary depending on factors such as the complexity of the part and the size of the production run.

Flexibility and complexity considerations in investment casting and sand casting

In addition to their unique advantages and considerations, investment casting and sand casting offer different possibilities for flexibility and complexity in the manufacturing industry based on investment casting vs sand casting possibilities.

When it comes to investment casting alternatives, this casting process allows for the production of intricate and complex designs.

This is made possible by the easily shaped and manipulated wax patterns.

Investment casting is particularly well-suited for creating parts with fine details and thin walls.

Examples of such parts include turbine blades, dental implants, and jewelry. Additionally, investment casting offers a wide range of materials that can be utilized to meet specific criteria and requirements.

These materials include ferrous and non-ferrous alloys. On the other hand, investment casting vs sand casting alternatives offer a flexible and cost-effective solution for various production needs.

Investment Casting vs Sand Casting

- Investment casting allows for the production of intricate and complex designs.

- Investment casting is well-suited for creating parts with fine details and thin walls, such as turbine blades, dental implants, and jewelry.

- Investment casting offers a wide range of materials, including ferrous and non-ferrous alloys, to meet specific criteria and requirements.

- Sand casting alternatives provide a flexible and cost-effective solution for various production needs.

Wilfley Aftermarket Parts Maximizing Returns with KLD Pumps: Investment vs Sand Casting