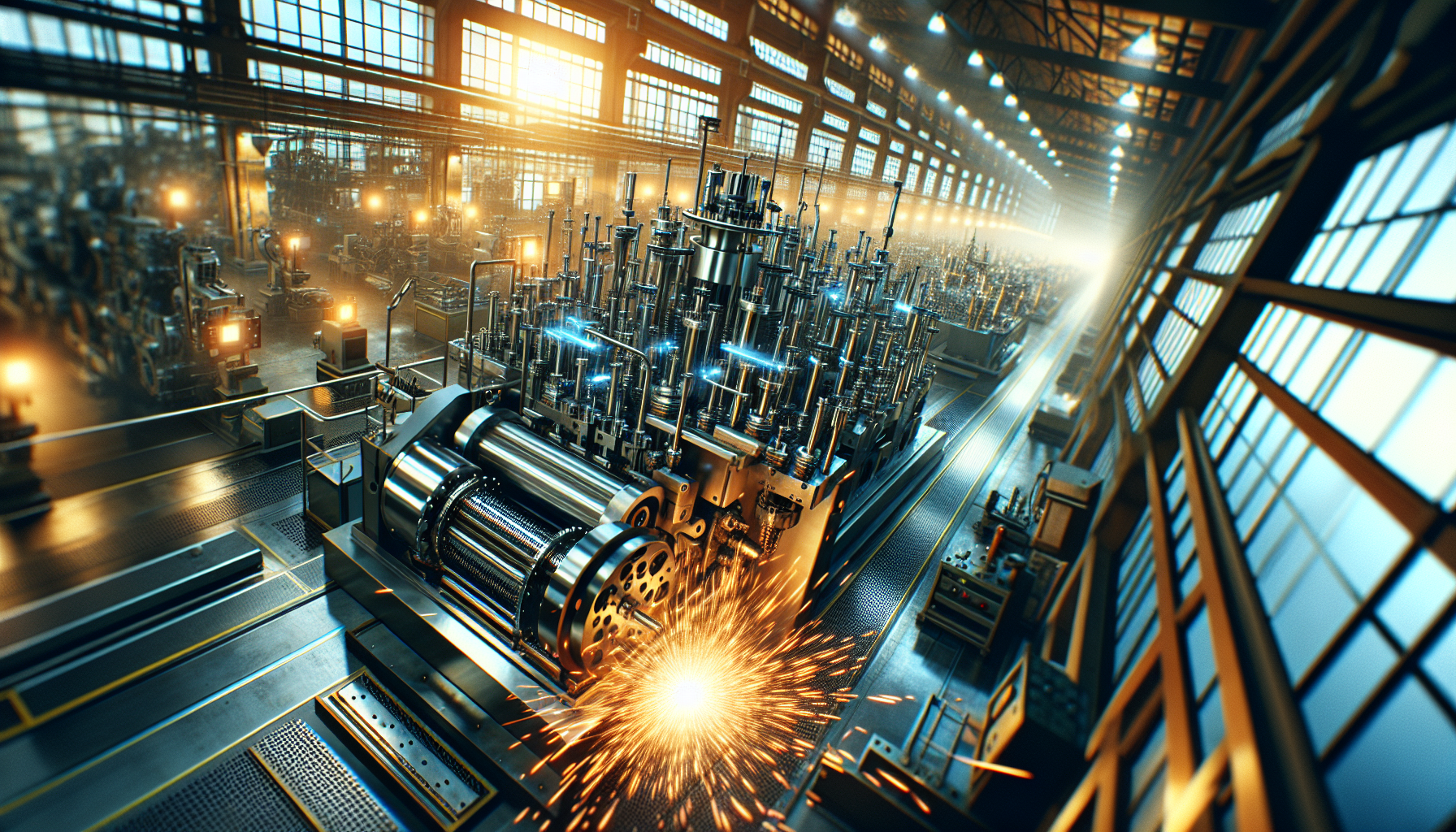

Industrial parts manufacturing plays a vital role in the broader manufacturing industry, providing essential components for various sectors. To ensure precise and high-quality results, it is essential to have a comprehensive understanding of the techniques and technologies involved in producing these parts.

Selecting the right materials and components for different applications is crucial.

The entire manufacturing process, from design to production and quality control, must be thoroughly evaluated to ensure efficiency and minimize errors.

It is equally important to manage costs, optimize the supply chain, and comply with regulatory standards.

By exploring the intricacies of industrial parts manufacturing, businesses and professionals can gain valuable insights and tools to overcome challenges and deliver top-quality products.

Visual aids, case studies, and success stories are effective ways to educate readers about KLDpumps.com and our superior parts and pricing for Wilfley, Krogh, Duro, and Flowserve parts manufacturing make us the top choice for all your industrial part needs.

Click here to learn more about: kldpumps.com

How to Choose the Right Manufacturing Process for Your Parts

When selecting a manufacturing process for your parts, it is important to consider several factors that contribute to project success, such as the capabilities of the manufacturing equipment and the efficiency of the manufacturing facility. These factors include specific part requirements like size and complexity, as well as material compatibility, desired quantity, lead time, production speed, budget constraints, and quality requirements.

By carefully evaluating these factors, you can make an informed decision about the manufacturing process that will best meet your needs and deliver the desired results.

Essential Tools and Materials for Industrial Parts Manufacturing

Industrial parts manufacturing requires the use of essential tools and materials to ensure efficient and high-quality production of parts. One crucial tool is the CNC machine, which allows for precise and automated fabrication of complex parts.

Cutting tools like drills, taps, and end mills are also necessary for shaping raw materials into desired components.

Precision measuring instruments such as calipers and micrometers ensure accuracy.

Commonly used metals include steel, aluminum, brass, and engineering plastics for their strength, durability, and heat resistance. Lubricants and coolants are essential in reducing friction and heat to enhance tool and machinery lifespan and improve part quality. To maintain consistency and maximize productivity, it is important for manufacturing businesses to stay updated on affordable and superior parts and pricing, like those offered by a reputable manufacturing company.

Industrial Parts Manufacturing

- CNC machines allow for precise and automated fabrication of complex parts.

- Cutting tools like drills, taps, and end mills are necessary for shaping raw materials into desired components.

- Precision measuring instruments such as calipers and micrometers ensure accuracy in the manufacturing process.

- Commonly used metals in industrial parts manufacturing include steel, aluminum, brass, and engineering plastics for their strength, durability, and heat resistance.

The Role of Precision Machining in Industrial Parts Production

Precision machining is an indispensable technique in the production of industrial parts, utilizing advanced manufacturing machinery and technology. Its advanced capabilities and impeccable accuracy allow for the creation of intricate and complex components that are vital across various industries.

The ability to achieve tight tolerances is one of the prime advantages of precision machining.

This ensures that the dimensions and specifications of the parts are controlled with an exceptional level of precision, guaranteeing a perfect fit and optimal performance in the manufacturing of machinery and other industrial components.

Precision machining offers unparalleled versatility, enabling the creation of parts from a wide array of materials, including metals, plastics, and composites. This empowers manufacturers to tailor components to their specific requirements, whether it be for strength, durability, or other desired properties. With precision machining, the possibilities for innovation and customization are limitless, allowing manufacturers to create groundbreaking products using cutting-edge manufacturing technology.

Meeting Unique Specifications and Requirements with Custom Parts Manufacturing

In today’s rapidly evolving industrial landscape, there is a growing demand for meeting unique specifications and requirements in terms of industrial solutions. Custom parts manufacturing offers businesses the perfect solution by providing components that are tailor-made to their exact needs.

Manufacturers can deliver parts that align with the client’s specific design, dimensions, or material requirements.

Custom parts manufacturing allows industries to embrace innovation and optimize performance, ensuring seamless compatibility with their machinery or systems.

This level of customization opens up endless possibilities, enabling businesses to thrive in the competitive market of industrial supply.

At KLDpumps.com, we specialize in superior parts and pricing for Wilfley, Krogh, Duro, and Flowserve parts.

Our commitment to delivering top-quality products ensures that businesses can rely on us for their custom parts manufacturing needs.

Custom Parts Manufacturing

- Custom parts manufacturing meets unique specifications and requirements in the industrial landscape.

- Manufacturers can deliver tailor-made components that align with specific design, dimensions, or material requirements.

- Custom parts manufacturing allows industries to embrace innovation and optimize performance.

- Businesses can thrive in the competitive market of industrial supply through the endless possibilities of customization.

The Importance of Quality Control in Industrial Parts Manufacturing

In the machining industry, quality control is of utmost importance in the production of metal parts manufacturing. It plays a crucial role in ensuring that every component meets the highest standards and specifications.

By implementing a robust quality control process, manufacturers can minimize defects, reduce waste, and enhance customer satisfaction.

Thorough inspections at various stages of the production process are a key aspect of quality control in industrial parts manufacturing.

This involves checking the raw materials for flaws, monitoring the manufacturing process for potential issues, and inspecting the final products for quality assurance.

To ensure accuracy and precision in the production of industrial parts, advanced technologies such as automated inspection systems and precision measuring tools are utilized. These technologies help in detecting any deviations from the required specifications, enabling manufacturers in the metalworking industry to make necessary adjustments and corrections to their machining parts or metal fabrication processes.

Streamlining Efficiency Automation in the Industrial Parts Industry

In today’s rapidly evolving industrial parts industry, streamlining efficiency through automation has become a top priority for manufacturers in precision parts manufacturing. By incorporating cutting-edge automation technologies, businesses can optimize production processes, reduce costs, and enhance overall productivity.

One crucial area of focus is the integration of smart machinery components, designed to seamlessly work with automated systems.

These components enable real-time monitoring, predictive maintenance, and improved quality control.

The utilization of Iot technology empowers manufacturers to gather valuable data from their machinery, enabling them to make informed decisions and optimize operations. Additionally, robotics and artificial intelligence (AI) can automate repetitive tasks, allowing the workforce to concentrate on more complex and value-added activities. AI-powered systems can analyze large volumes of data, identify patterns, and make precision engineering a seamless reality.

Exploring Different Industries that Rely on Industrial Parts

The field of custom parts manufacturing is an industry that heavily relies on precision manufacturing techniques to meet the specific demands of various sectors including automotive parts manufacturing and aerospace parts manufacturing. Companies in this sector specialize in producing unique and tailor-made components to meet the specific needs of their clients.

They employ custom machining and custom fabrication techniques to ensure precise measurements and high-quality finishes.

This sector plays a crucial role in supporting diverse industries by providing specialized parts that cannot be readily found in standard manufacturing processes.

The ability to create custom parts manufacturing is especially valuable in industries such as automotive parts manufacturing and aerospace parts manufacturing, where complex and intricate components are required for optimal performance.

The Future of Industrial Parts Trends and Innovations

With the continuous advancements in electronic parts manufacturing, the future of industrial parts trends and innovations looks promising, particularly in the field of industrial automation. As technology continues to evolve, industries can expect a shift towards smart factories that utilize cutting-edge technology to improve efficiency and reduce operational costs.

Sustainability will also be a top priority, as the industry embraces cleaner and greener manufacturing processes.

Technologies like 3D printing and additive manufacturing will enable the production of highly customized parts, reducing the need for large inventories and minimizing waste.

As industrial automation progresses, the future of manufacturing machinery components holds significant potential for growth and innovation. For superior parts and pricing, KLDpumps.com offers a wide range of options for various brands such as Wilfley, Krogh, Duro, and Flowserve.

Industrial Automation and Manufacturing Machinery Components

- The continuous advancements in electronic parts manufacturing have led to increased efficiency and reduced operational costs in industrial automation.

- Smart factories, utilizing cutting-edge technology, are expected to become the future of industrial automation, improving overall efficiency in the manufacturing process.

- The adoption of cleaner and greener manufacturing processes is a top priority for the industry, ensuring sustainability in the production of industrial parts.

- Technologies like 3D printing and additive manufacturing enable the production of highly customized parts, reducing the need for large inventories and minimizing waste in the manufacturing industry.