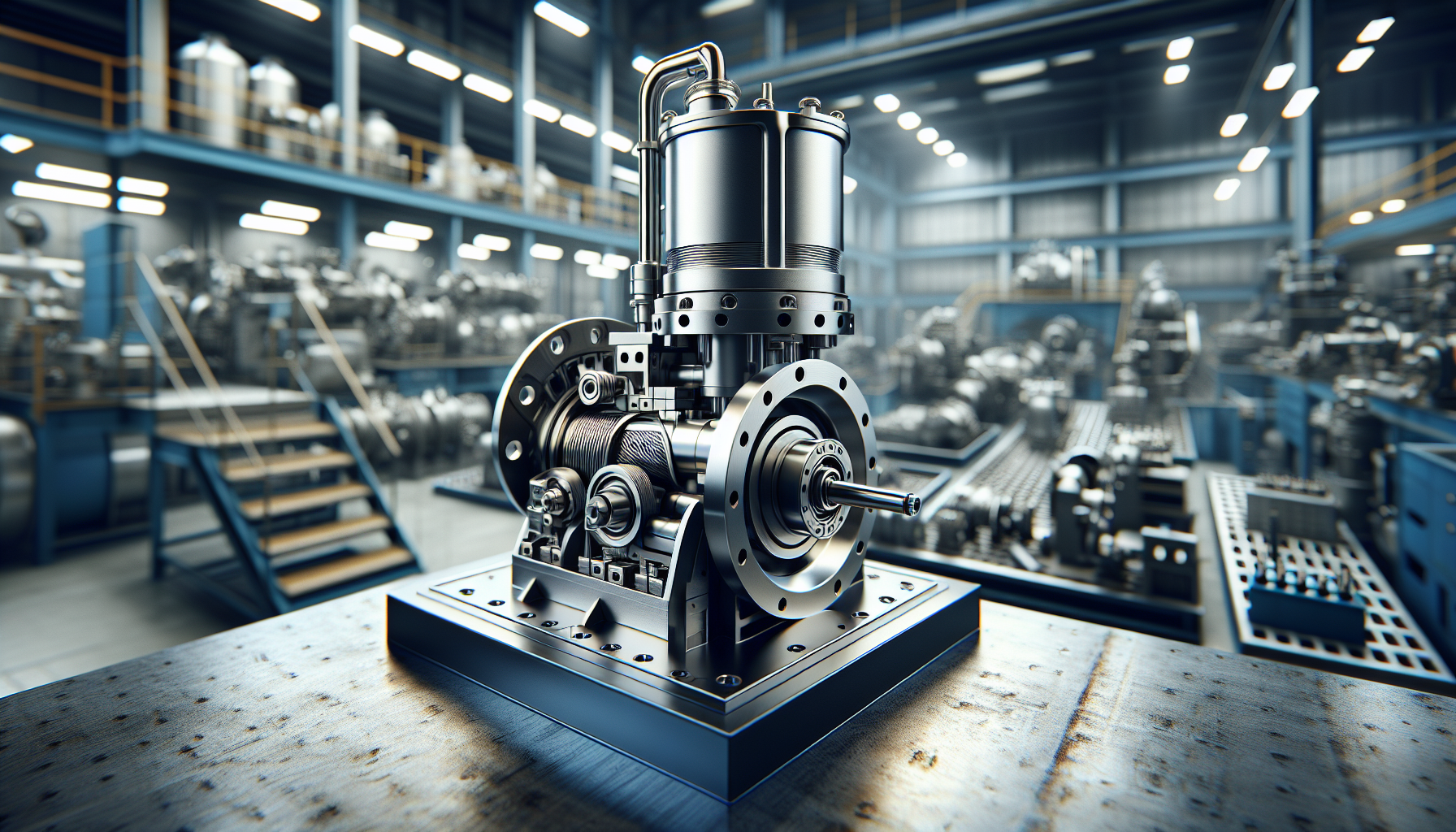

Aftermarket pump components, such as pump replacement parts and pump repair parts, are vital for enhancing the performance and efficiency of your pump system. These parts are specifically designed to replace worn-out or damaged components, guaranteeing optimal functionality.

One significant advantage of aftermarket pump parts is their compatibility with a wide range of pump models and brands.

Whether you own a centrifugal, submersible, or diaphragm pump, finding replacement parts that fit your specific system is hassle-free.

This versatility eliminates the need for extensive searches and allows for a quick restoration of your pump’s functionality. Choosing aftermarket parts proves cost-effective as they offer the same level of performance and reliability as original equipment manufacturer (OEM) parts at a lower cost.

For superior parts and pricing options for Wilfley, Krogh, Duro, Flowserve, and more, KLDpumps. com is the ultimate source.

Click here to learn more about: kldpumps.com

Essential Components of an Aftermarket Pump

When it comes to aftermarket pump components, the quality and functionality of pump spare accessories play a crucial role. These accessories, which include pump parts and components, play a vital role in maintaining the efficiency and performance of the pump system.

By utilizing dependable aftermarket pump replacement parts and spare components, you can ensure that your pump operates at its optimal level.

This helps to minimize the risk of downtime and costly repairs.

To guarantee a smooth fit and reliable performance, it is important to select high-quality aftermarket pump repair accessories that are compatible with your specific pump model.

Choosing the Right Replacement Parts for Your Pump

When it comes to choosing replacement parts for your pump, there are a few important factors to keep in mind such as the availability of pump parts for sale from a reliable pump parts supplier. First and foremost, consider the make and model of your pump.

Different pumps have different requirements, and using incorrect parts can lead to inefficiency or damage.

To ensure you’re selecting the right parts, consult the manufacturer’s instructions or seek expert guidance.

Another crucial factor to consider is the quality of the replacement parts. While aftermarket pump options may offer cost savings, it’s important to choose reputable suppliers that provide high-quality components.

Look for suppliers with a proven track record and positive customer reviews to ensure reliability and durability. Consider the warranty and customer support offered by the supplier.

Having reliable support in case of any issues provides peace of mind and ensures a smooth experience.

Don’t forget to consider the specific requirements of your pump, such as size and power. Taking these factors into account will help you make the best decision for your pump’s replacement, whether it be purchasing pump parts online from a reliable supplier, or exploring the various options available at a trusted pump parts store.

| Factors to Consider | Importance |

|---|---|

| Availability of pump parts from a reliable supplier | High |

| Make and model compatibility | High |

| Quality of replacement parts | High |

| Warranty and customer support | Medium |

| Specific requirements (size and power) | Medium |

Enhancing Performance with Pump Accessories

In addition to choosing the appropriate replacement parts for your pump, it is also important to consider other pump accessories that can enhance its performance, such as those available in the pump parts catalog from a reputable pump parts retailer. One such accessory worth considering is a pump controller.

A pump controller is responsible for regulating the flow, pressure, and speed of the pump, thereby optimizing its efficiency and preventing any potential issues such as overloading or underperformance.

A pump controller can provide valuable data and real-time monitoring, enabling you to monitor and adjust the performance of your pump system as necessary.

It is advisable to invest in a high-quality pump controller from a reputable retailer or wholesaler specializing in pump parts. By doing so, you can significantly improve the overall performance of your pump system

Finding Reliable Suppliers for Aftermarket Pump Components

When it comes to sourcing aftermarket pump components, one of the key factors to consider is finding reliable suppliers, such as an aftermarket pump component distributor or manufacturer. This is crucial to ensure the smooth functioning of your pump system.

To make your search for reliable suppliers easier, it is recommended to utilize a comprehensive pump parts database or a pump parts finder tool.

These tools can help you find trustworthy suppliers who specialize in pump replacement parts and pump spares.

By using these resources, you can easily identify reputable aftermarket pump component distributors or manufacturers who offer a wide range of high-quality products. Investing time in finding reliable suppliers can save you effort and ensure the longevity of your pump system.

KLDpumps.com is a reliable source for aftermarket pump components. They offer superior parts and competitive pricing for popular pump brands like Wilf, making them the go-to pump parts finder website.

| Benefits of Using Pump Parts Database | Benefits of Using Pump Parts Finder Tool |

|---|---|

| Access to a wide range of reliable suppliers. | Efficient and convenient search for trustworthy suppliers. |

| Specialization in pump replacement parts and pump spares. | Identification of reputable aftermarket pump component distributors or manufacturers. |

| Assurance of high-quality products. | Time-saving and effort-saving in finding reliable suppliers. |

Factors to Consider When Selecting Spare Parts for Your Pump

When selecting spare parts for your pump, it is crucial to consider several factors such as the aftermarket pump component inventory offered by the retailer. One key aspect to take into account is the availability of the necessary parts.

It is essential to choose a retailer, wholesaler, dealer, seller, shop, or vendor of aftermarket pump components that offers a broad inventory of spare parts.

This will simplify the process of locating the specific components you need for your pump.

Having access to a comprehensive aftermarket pump component catalog or list can aid in promptly identifying and comparing various options, allowing you to make an educated choice.

Saving Money with Aftermarket Pump Repair Parts

Aftermarket pump repair parts are becoming increasingly popular for businesses looking to save money on pump repairs, as they can easily find the necessary components through the comprehensive aftermarket pump component finder website. These parts offer a cost-effective solution compared to original equipment manufacturer (OEM) parts.

One of the main advantages of aftermarket parts is their affordability due to independent production, resulting in significant cost savings.

The extensive selection available in the aftermarket pump component database allows businesses to find the perfect match for their specific pump model.

It is important to ensure compatibility to avoid any potential issues. To learn more about superior parts and pricing for brands like Wilfley, Krogh, Duro, and Flowserve, visit KLDpumps.com

Aftermarket Pump Repair Parts

- Aftermarket pump repair parts are increasingly popular for businesses looking to save money on pump repairs.

- These parts offer a cost-effective solution compared to original equipment manufacturer (OEM) parts.

- Aftermarket parts provide significant cost savings due to independent production.

- The extensive selection available in the aftermarket pump component database allows businesses to find the perfect match for their specific pump model.

Maintenance Tips for Prolonging the Life of Pump Parts

Regular maintenance is essential for maintaining the longevity and optimal performance of pump parts, whether you are a pump components manufacturer, distributor, retailer, wholesaler, dealer, seller, shop, or vendor. By following a few simple tips, you can effectively prolong the life of these components and avoid costly repairs or replacements.

One important aspect of maintenance is conducting regular inspections to check for signs of wear or damage.

It is crucial to address issues such as leaks, cracks, or excessive vibration early on to prevent further damage and extend the lifespan of the pump parts.

Keeping the pump clean by regularly removing dirt, debris, or buildup can help prevent clogs and improve overall efficiency. Proper lubrication according to the manufacturer’s recommendations is also vital to reduce friction and wear, resulting in longer-lasting components.

Monitoring the pump’s performance and promptly addressing any changes in its operation, such as unusual noises, decreased flow rate, or increased energy consumption, can prevent further damage and extend the life of the pump.

Troubleshooting Common Issues with Pump Components

When troubleshooting common issues with a pump components inventory, it is important to identify the root cause of the problem. Inadequate suction conditions or improper pump design can often be the culprit.

Once the cause is determined, steps can be taken to address the issue, such as increasing inlet pressure, improving suction conditions, or redesigning the pump.

Wear and tear is another common problem that can lead to reduced performance and efficiency.

Factors like abrasive particles in the fluid, inadequate maintenance, or poor quality components can contribute to this issue. Regular inspection and maintenance of the pump components, including cleaning or replacing worn-out parts and ensuring proper lubrication, are essential to mitigate this problem.

In some cases, it may be necessary to replace the entire pump component to restore optimal performance. When selecting replacement parts or spares, it is crucial to choose high-quality ones from a reliable pump components catalog.

Pump Components

- Inadequate suction conditions or improper pump design can often be the root cause of common issues with a pump components inventory.

- Abrasive particles in the fluid, inadequate maintenance, or poor quality components can contribute to wear and tear, leading to reduced performance and efficiency.

- Regular inspection, maintenance, cleaning, and replacing worn-out parts, as well as ensuring proper lubrication, are essential to mitigate wear and tear problems.

- In some cases, replacing the entire pump component may be necessary to restore optimal performance.