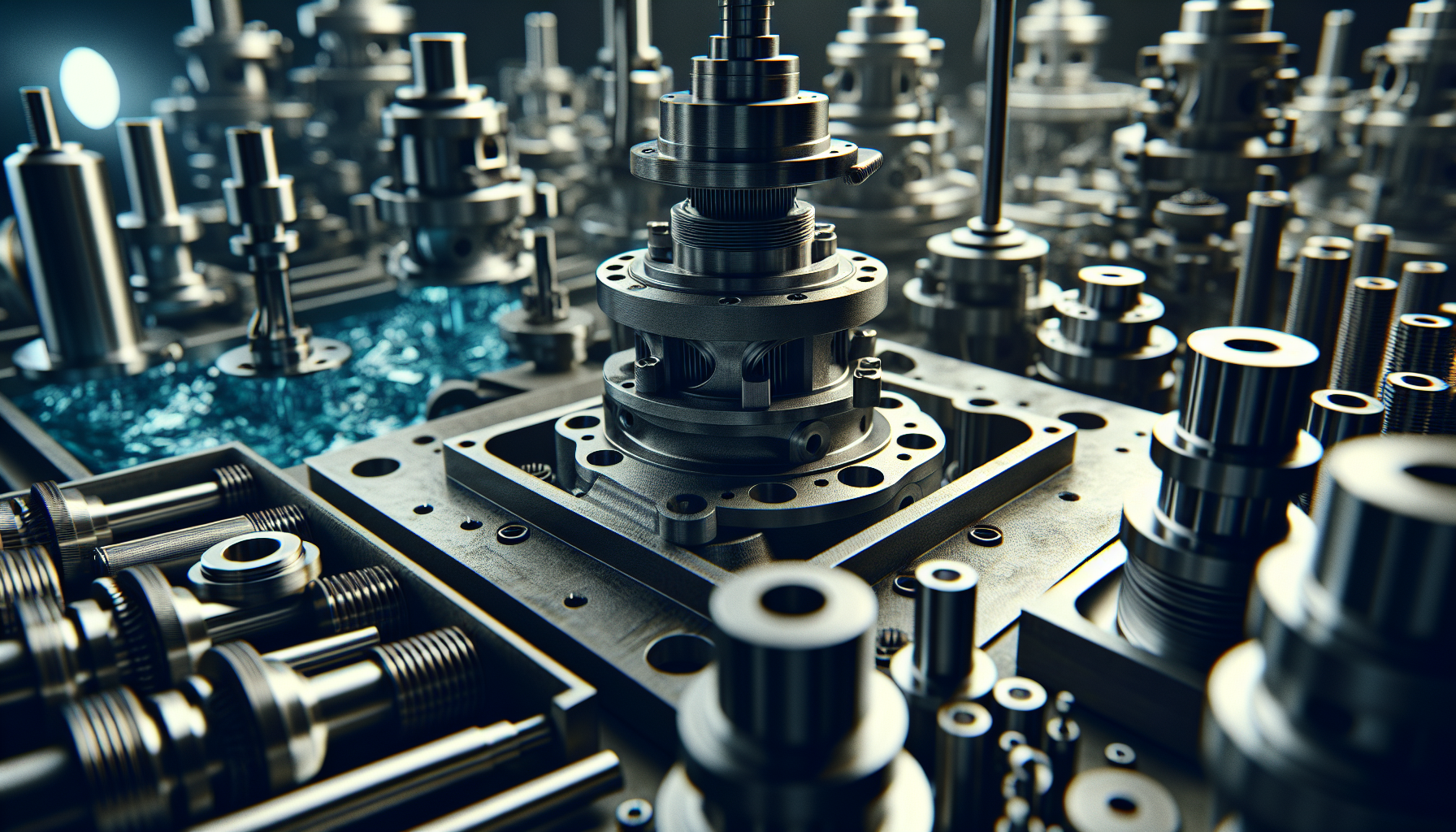

When it comes to improving efficiency and optimizing pump performance, custom pump parts are a game-changer. These specialized components are designed through custom manufacturing, offering companies the opportunity to tailor pump parts to their specific needs and requirements.

This precise fit enhances overall performance and reduces energy consumption.

Additionally, aftermarket pump parts are available as cost-effective replacements for OEM components.

These parts extend the lifespan of pumps and improve efficiency. KLD Pumps, a reputable provider of custom pump parts, offers a wide range of high-quality aftermarket solutions.

With their superior parts and competitive pricing, KLD Pumps can meet the unique needs of various industries, including Wilfley, Krogh, Duro, and Flowserve parts. Visit KLDpumps.com to learn more about their products and expertise.

Click here to learn more about KLD Pumps

How to Choose the Right Pump Parts

Choosing the right pump parts, specifically custom aftermarket parts can greatly impact the performance and longevity of your pump system. An important consideration in this process is the availability of custom aftermarket parts.

These parts are specifically designed to meet your individual needs and requirements, resulting in optimal performance and efficiency.

With advancements in pump parts manufacturing, companies now have the option to have custom parts created specifically for their pump systems.

This not only enhances overall performance but also reduces energy consumption. By investing in aftermarket manufacturing, you can prolong the lifespan of your pumps and ensure seamless operations.

Benefits of Using Aftermarket Parts

Aftermarket parts are not only beneficial for those in industries such as custom manufacturing or aftermarket pump parts manufacturing, but they also come with a range of advantages. One of the main benefits is cost savings.

Aftermarket components are often more affordable than OEM parts while still maintaining the same level of functionality.

This is especially advantageous for businesses operating on tight budgets or individuals looking to save money on equipment maintenance or repairs.

Using aftermarket parts can be a sustainable choice. By opting for these components, users can extend the lifespan of their equipment, reducing the need for new purchases and minimizing waste.

This not only has a positive impact on the environment but also contributes to a more sustainable future.

Aftermarket parts provide a valuable alternative to OEM components. Whether it’s for custom manufacturing, aftermarket pump parts, or any other equipment needs, these high-quality components offer increased availability, cost savings, and improved performance for custom pump parts manufacturing.

Key Considerations for Custom Manufacturing

When it comes to custom manufacturing, businesses need to consider various important factors such as manufacturing custom aftermarket parts. From the design phase to the selection of materials and components, each step contributes to the delivery of high-quality products that meet specific requirements.

One crucial consideration is the design phase, where careful attention should be given to ensure the final product meets all specifications and requirements.

Businesses should also consider the selection of materials and components, as these choices greatly impact product performance and durability.

Additionally, manufacturability is another key consideration, as it involves assessing the feasibility and potential challenges of manufacturing unique or complex products. Effective communication and collaboration with the manufacturing partner are also essential for the successful manufacturing of custom aftermarket parts.

Enhancing Performance with Custom Parts

When it comes to addressing inefficiencies in your machinery, custom manufacturing pump parts for the aftermarket can be a game-changer. These parts are designed and manufactured specifically to target problem areas, allowing you to overcome limitations and optimize performance.

Whether you need to enhance the flow rate of an aftermarket pump system or improve the precision of a specialized machine, custom parts can make a significant difference.

But it’s not just about performance.

Custom parts also offer increased compatibility, ensuring seamless integration with your existing equipment. Upgrading or modifying machinery can often pose challenges in finding off-the-shelf parts that fit perfectly.

With custom manufacturing, you can eliminate compatibility issues and ensure smooth operation by creating parts that perfectly fit and function.

When considering custom parts, it’s crucial to partner with a reputable manufacturer.

KLD Pumps is a trusted company specializing in custom manufacturing. With extensive experience in producing custom manufacturing pump parts for aftermarket, they offer superior parts and pricing for brands.

| Benefits of Custom Manufacturing Pump Parts | Off-the-Shelf Parts |

|---|---|

| Increased Performance | Standard Performance |

| Enhanced Compatibility | Limited Compatibility |

| Perfect Fit and Function | Potential Fit Issues |

The Role of Manufacturing in Parts Quality

Manufacturing aftermarket pump parts for custom applications requires careful attention to detail and precision. The selection of materials plays a crucial role in ensuring the quality and durability of these parts.

Manufacturers must consider factors such as strength, corrosion resistance, and compatibility with other components to meet specific requirements.

Advanced technologies and skilled technicians are vital in overseeing the manufacturing process to ensure accuracy and consistency.

Quality control measures, including rigorous testing and inspection procedures, guarantee that only high-quality components reach the market. Through custom manufacturing, manufacturers can deliver reliable and efficient solutions that seamlessly fit into existing systems.

Exploring Options for Aftermarket Manufacturing

Aftermarket manufacturing is a valuable option for businesses seeking custom pump parts for their unique product needs. It allows companies to create custom-made products that adhere to their specific requirements, ensuring high-quality standards and seamless integration into existing systems.

Having reliable replacements readily available can significantly reduce downtime and enhance operational efficiency.

One notable player in this industry is KLD Pumps, a reputable manufacturer known for their expertise in producing aftermarket parts for various industries.

KLD Pumps offers superior parts and pricing for renowned brands like Wilfley, Krogh, Duro, and Flowserve. By exploring the capabilities and offerings of manufacturers like KLD Pumps businesses can find valuable insights and potential solutions for their aftermarket manufacturing needs.

Benefits of Aftermarket Manufacturing

- Custom-made products ensure high-quality standards and seamless integration into existing systems.

- Reliable replacements readily available can significantly reduce downtime and enhance operational efficiency.

- KLD Pumps is a reputable manufacturer known for producing aftermarket parts for various industries.

- KLD Pumps offers superior parts and pricing for renowned brands like Wilfley, Krogh, Duro, and Flowserve.

Impact of Manufacturing on Pricing

Aftermarket pump parts custom manufacturing has a profound impact on the pricing of products. Various factors influence the final cost.

The cost of raw materials plays a significant role.

Fluctuations in their prices directly affect manufacturing costs and, subsequently, the pricing of the final product.

Labor costs also contribute significantly to overall manufacturing costs. Wages, benefits, and productivity levels all play a part in determining the cost of production.

The use of advanced technology and automation can streamline processes, reduce labor costs, and increase productivity. This, in turn, leads to more competitive pricing.

Additionally, economies of scale come into play.

As production volume increases, manufacturers can offer lower prices.

Quality control and customization options can also affect pricing. The more rigorous the quality control measures, the higher the manufacturing costs.

Tips for Finding Reliable Manufacturers

When it comes to sourcing reliable manufacturers for your specific needs, there are several essential tips to follow, especially when it involves custom manufacturing aftermarket pump parts. First and foremost, it is crucial to find a manufacturer that specializes in custom manufacturing and has a proven track record of delivering high-quality products.

This expertise and experience ensure that they understand your unique requirements and can meet them effectively.

Another crucial aspect is researching the manufacturer’s reputation, reliability, and customer feedback.

By reading reviews and testimonials from previous customers, you can gain insights into their level of professionalism and customer satisfaction.

In your search for a reliable manufacturer, consider visiting KLDpumps.com.

They are known for their superior parts and pricing for well-known brands like Wilfley, Krogh, Duro, and Flowserve. Their expertise in custom manufacturing, along with positive customer feedback, makes them a reliable choice for your manufacturing needs.

The Ultimate Guide to Aftermarket Pump Parts: Enhance Performance and Efficiency