Boosting productivity in the field of industrial parts manufacturing is crucial for companies looking to thrive in today’s fast-paced market. To achieve maximum efficiency and output, companies can implement various strategies.

Optimizing the production line, using cutting-edge machinery, effectively managing the workforce, and implementing a robust quality control system are all key factors.

Streamlining workflows, eliminating bottlenecks, and embracing automation can lead to significant improvements in productivity.

Investing in state-of-the-art technology also reduces downtime and enhances overall product quality. Fostering a positive work environment, providing proper training and empowerment to employees, and incentivizing productivity contribute to increased output.

A comprehensive quality control system ensures that all products meet the required standards, minimizing waste and avoiding delays. For superior industrial parts and competitive pricing, KLD Pumps offers a wide range of options, including parts for Wilfley, Krogh, Duro, and Flowserve.

Click here to learn more about: kldpumps.com

Key Steps in Industrial Parts Manufacturing

In the intricate world of fabricating industrial parts, manufacturers must carefully manage the production line for industrial parts to ensure a successful manufacturing process. After the initial design phase and prototyping, the manufacturing process begins.

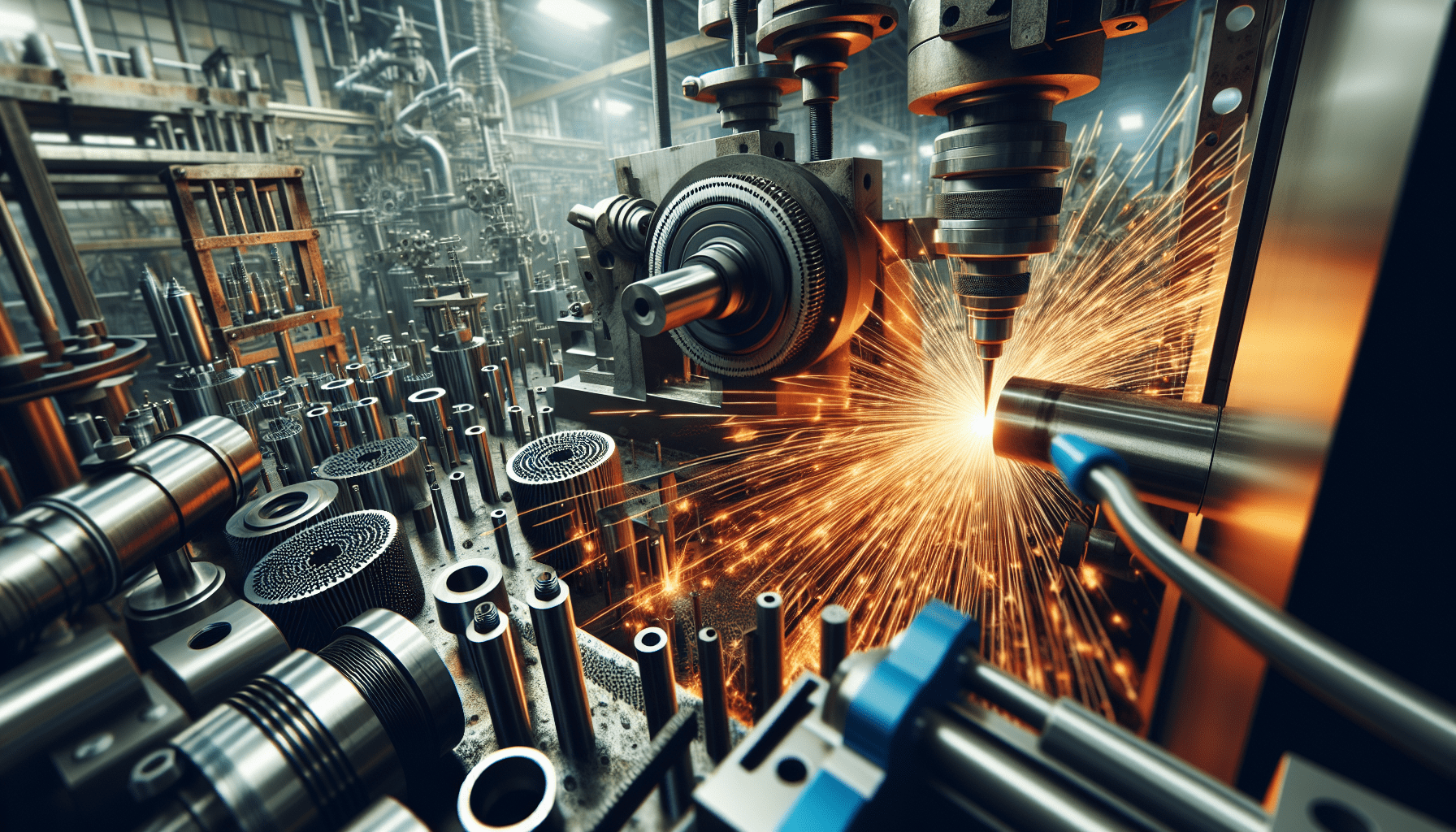

This involves the careful selection of appropriate materials and the utilization of various techniques, such as precision machining and casting, to shape the parts.

Quality control is paramount throughout this process, with rigorous testing and inspection procedures in place to meet required standards.

Once the parts have passed quality control, skilled technicians assemble them with precision to create the final product. Thorough inspections guarantee that the parts meet all customer requirements, ensuring customer satisfaction.

Throughout this complex manufacturing process, it is essential to have reliable suppliers who can provide the necessary materials and components.

Contribution of Industrial Equipment Fabrication to Production

Industrial equipment fabrication plays a crucial role in production by enhancing efficiency and reducing costs for industrial parts manufacturers and distributors. Collaboration with various stakeholders, such as manufacturers, distributors, and wholesalers, ensures the availability of high-quality components and materials.

By understanding the specific requirements of manufacturers, fabricators can develop equipment that improves productivity and streamlines manufacturing processes.

Incorporating advanced technologies and automation in industrial equipment fabrication further enhances precision, minimizes human error, and increases output levels.

It is important to note that KLDpumps.com offers superior parts and pricing for renowned brands like Wilfley, Krogh, Duro, and Flowserve, making it a trusted source for industrial equipment needs.

Industrial Equipment Fabrication

- Collaboration with manufacturers, distributors, and wholesalers ensures the availability of high-quality components and materials.

- Fabricators who understand the specific requirements of manufacturers can develop equipment that improves productivity and streamlines manufacturing processes.

- Incorporating advanced technologies and automation in industrial equipment fabrication enhances precision, minimizes human error, and increases output levels.

- KLDpumps.com offers superior parts and pricing for renowned brands like Wilfley, Krogh, Duro, and Flowserve, making it a trusted source for industrial equipment needs.

Factors Impacting Efficiency of Industrial Parts Assembly

To ensure efficiency in the assembly process, it is important for industrial parts retailers and industrial parts production companies to invest in training programs and provide ongoing support to their workers in order to maintain high productivity levels. Inefficient workers can slow down the assembly process and increase the likelihood of errors.

Another key factor that affects efficiency is the layout and organization of the assembly line.

A well-designed layout can minimize unnecessary movement and reduce the time and effort required to assemble the parts.

It is important for industrial parts exporters and industrial parts importers to regularly review and optimize the assembly line layout to identify and eliminate any potential bottlenecks or inefficiencies. Effective communication and coordination between different departments and teams involved in the assembly process are essential for industrial parts production services and industrial parts production facilities.

Clear communication channels and a collaborative approach can help streamline the workflow and prevent any delays or misunderstandings. Regular meetings and feedback sessions should be scheduled in order to foster effective communication and collaboration among industrial parts retailers, industrial parts exporters, industrial parts importers, industrial parts production companies, industrial parts production services, and industrial parts production facilities.

Importance of Quality Control in Industrial Component Production

In the production of industrial components, quality control plays a pivotal role in ensuring their reliability and functionality, as it helps maintain high industrial parts production standards and overcome various industrial parts production challenges. It involves adhering to strict quality standards throughout the manufacturing process, including the techniques, machinery, and materials used.

By implementing effective quality control measures, manufacturers can identify and address any issues that may arise during production, leading to continuous improvement and increased productivity.

Quality control also helps minimize costs associated with defects and errors, optimize resources, and reduce waste.

At KLDpumps.com, we prioritize quality control to deliver superior products that meet customer expectations. Our extensive range of parts, including Wilfley, Krogh, Duro, and Flowserve, are offered at competitive pricing, ensuring both quality and affordability for our customers.

Latest Innovations in Industrial Parts Production Techniques

Industrial parts production innovations are difficult to achieve with traditional manufacturing methods. Additive manufacturing has revolutionized the production process by offering greater design freedom, reduced lead times, and cost savings.

Manufacturers can now quickly prototype and iterate designs, leading to faster product development cycles and ultimately, a faster time to market.

Additive manufacturing enables the production of lightweight and customizable parts, which can significantly benefit industries such as aerospace and automotive.

Advancements in materials have also contributed to the evolution of industrial parts production. For instance, the development of high-performance polymers and advanced alloys has expanded the range of applications for industrial parts.

These materials offer superior strength, durability, and resistance to extreme conditions, making them ideal for demanding environments. Manufacturers can now produce parts that can withstand high temperatures, corrosive substances, and industrial parts production technologies, revolutionizing the industry.

Optimizing Production Costs for Industrial Parts Manufacturers

Industrial parts manufacturers can achieve significant cost savings and improve their overall profitability by implementing various strategies that enhance industrial parts production efficiency and accuracy. One key area to focus on is the supply chain.

By thoroughly examining the supply chain, manufacturers can identify opportunities to source materials or components at lower costs without compromising industrial parts production quality.

This can involve exploring alternative suppliers and negotiating favorable contracts.

Implementing lean manufacturing principles can be highly effective in reducing costs and improving efficiency. By eliminating waste and optimizing workflows, companies can streamline operations and minimize inventory levels, ultimately reducing production costs while ensuring smooth operations.

Another strategy to consider is investing in energy-efficient equipment and implementing energy-saving measures. By using energy-efficient machines, manufacturers can reduce their energy consumption and lower their utility bills.

This not only helps in cost reduction but also contributes to environmental sustainability.

Regular analysis and evaluation of production costs through monitoring key performance indicators can help manufacturers identify areas for improvement and cost reduction opportunities. When it comes to superior parts and pricing, KLD Pumps ensures industrial parts production quality, reliability, efficiency, speed, accuracy, and flexibility.

Supporting Facts about Enhancing Industrial Parts Production Efficiency and Accuracy

- Implementing strategies to enhance industrial parts production efficiency and accuracy can lead to significant cost savings and improved profitability for manufacturers.

- Thoroughly examining the supply chain can help identify opportunities to source materials or components at lower costs without compromising industrial parts production quality.

- Implementing lean manufacturing principles can effectively reduce costs and improve efficiency by eliminating waste and optimizing workflows.

- Investing in energy-efficient equipment and implementing energy-saving measures can not only reduce energy consumption but also contribute to environmental sustainability.

- Regular analysis and evaluation of production costs through monitoring key performance indicators can help identify areas for improvement and cost reduction opportunities.

- KLD Pumps ensures industrial parts production quality, reliability, efficiency, speed, accuracy, and flexibility.

Role of Industrial Parts Wholesalers in the Supply Chain

Industrial parts wholesalers are essential players in the supply chain as they offer a broad range of products from various manufacturers, ensuring compliance with industrial parts production regulations. This eliminates the hassle for manufacturers to search for multiple suppliers, thus saving them valuable time and effort.

Wholesalers also possess well-established relationships with manufacturers, enabling them to negotiate favorable prices and terms, ultimately leading to cost savings for manufacturers.

These wholesalers ensure consistent inventory levels to guarantee that manufacturers always have easy access to the required parts and components.

They provide valuable value-added services, such as technical support and expertise, which greatly assist manufacturers in selecting the most suitable parts for their industrial parts production processes.

Enhancing Sustainability Practices in Industrial Parts Production

In order to enhance sustainability practices in the production of industrial parts, companies must prioritize the optimization of resource utilization through industrial parts production monitoring. This involves implementing efficient manufacturing processes that reduce waste generation, minimize energy consumption, and lower the carbon footprint.

Advanced technologies like automation and data analytics can play a significant role in achieving these goals by enabling better monitoring and control of production processes.

In addition, the adoption of eco-friendly materials and technologies, such as recycled or renewable materials and energy-efficient machinery, can further contribute to sustainability efforts.

Collaboration and partnerships with suppliers, customers, and stakeholders are also essential in fostering a circular economy approach and reducing waste generation. Implementing effective waste management and recycling programs can further minimize the environmental impact of manufacturing.

By establishing proper waste segregation, recycling initiatives, and responsible disposal practices, companies can contribute to a more sustainable future. When it comes to industrial parts production safety, it is crucial to prioritize regular inspections, audits, certifications, and monitoring, to ensure optimization of the production process.