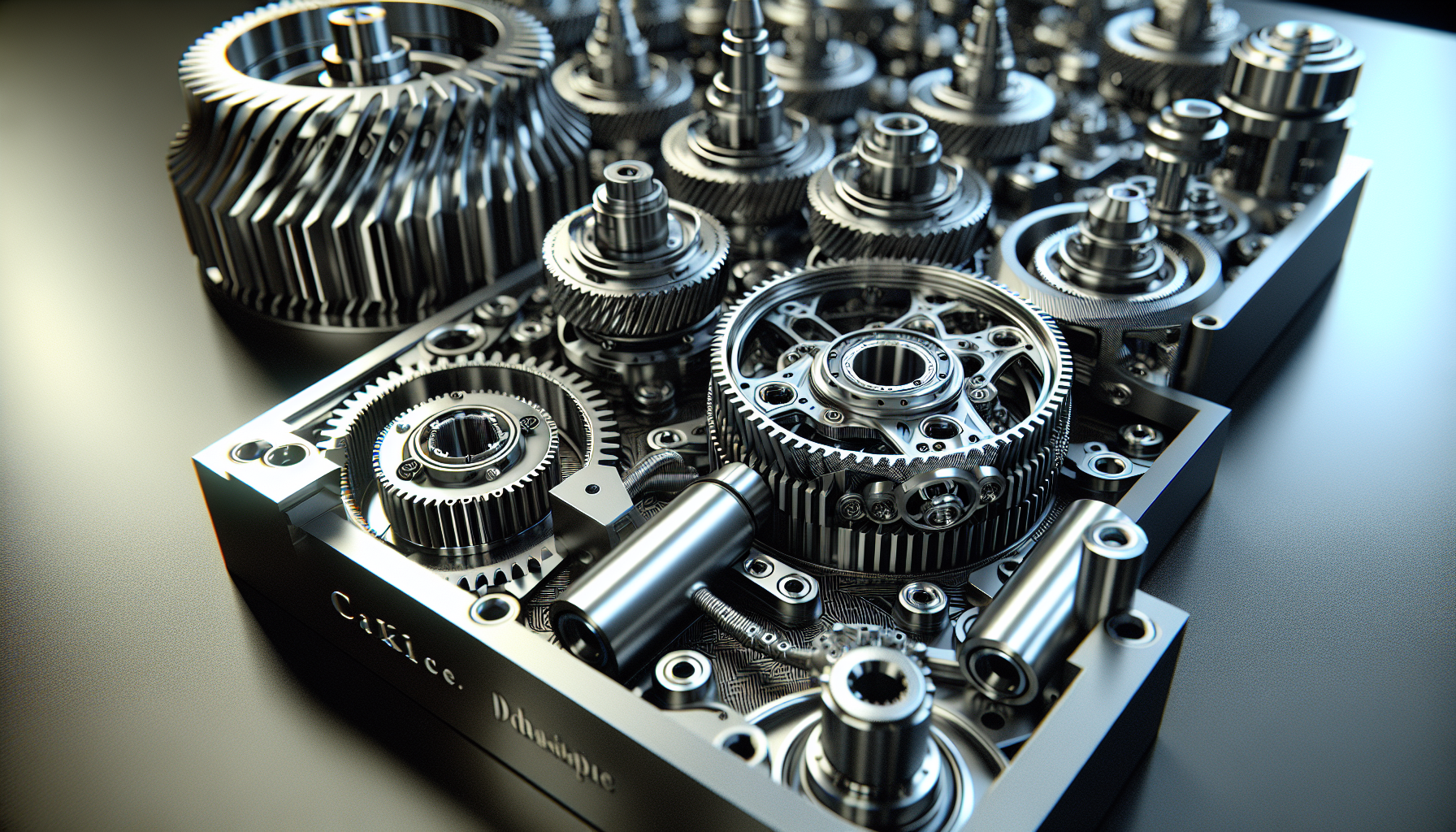

Custom manufacturing parts, such as precision machined components, offer businesses tailored solutions to enhance their operations by providing custom parts that perfectly fit their needs. These manufacturing parts are designed to meet specific requirements, ensuring optimal performance and efficiency.

By opting for custom fabrication services, businesses can address unique challenges and gain a competitive edge in their industries.

The versatility of these parts is worth highlighting as they can be designed and manufactured to fit various applications, from automotive and aerospace to medical and electronics.

In this regard, KLD Pumps stands out with superior parts and pricing for brands like Wilfley, Krogh, Duro, and Flowserve.

Click here to learn more about KLD Pumps

Essential Custom Manufacturing Parts for Businesses

When it comes to essential custom manufacturing parts, businesses benefit from a wide range of manufacturing elements and custom units that cater to their unique needs. These specialized manufacturing accessories are designed and fabricated to meet specific industry demands, providing businesses with tailor-made solutions for enhanced productivity and efficiency.

By utilizing these custom accessories, businesses can optimize their manufacturing processes and improve overall performance.

From precision machined components to custom fabrication services, these essential parts play a vital role in helping businesses stay ahead in today’s competitive marketplace

Improving Product Quality with Custom Manufacturing Parts

In addition to optimizing manufacturing processes, using custom manufacturing parts can contribute to improving the quality of final products. These precision machined components are designed and manufactured to meet the unique requirements of various industries.

By ensuring that each component fits perfectly and functions flawlessly within the product, businesses can eliminate potential issues caused by ill-fitting or generic parts.

This leads to a higher level of quality and reliability.

Custom fabrication services also allow for manufacturing items tailored to specific needs, resulting in enhanced durability, performance, and overall customer satisfaction. At KLDpumps.com, we offer superior parts at competitive prices for Wilfley, Krogh, Duro, and Flowserve, ensuring the highest quality for your products.

Custom Manufacturing Parts

- Custom manufacturing parts optimize manufacturing processes.

- Precision-machined components meet the unique requirements of various industries.

- Using custom fabrication services leads to enhanced durability and performance.

- KLDpumps. com offers superior parts at competitive prices for Wilfley, Krogh, Duro, and Flowserve.

Considerations for Choosing a Parts Supplier

When it comes to selecting a supplier for parts, there are several crucial factors that you should take into account such as the reliability and quality of manufacturing parts suppliers.

The expertise of the supplier in the specific industry or field that you are working in is extremely important.

This ensures that they have the necessary knowledge and skills to deliver high-quality parts.

It is also important to consider the track record and reputation of the supplier in providing reliable and durable parts.

This helps to minimize the risk of product defects or failures.

Another important factor to evaluate is the supplier’s production capabilities and capacity, as well as their ability to handle custom or specialized manufacturing processes.

While cost is an important consideration, it is not advisable to compromise on quality just to save money. Communication and customer service should also be taken into account, as they ensure that your needs and expectations are met, whether you opt for manufacturing supplies or custom parts suppliers.

Enhancing Production Efficiency with Custom Parts

Custom parts play a crucial role in enhancing production efficiency for companies through custom parts fabrication and manufacturing parts assembly. These parts are designed and fabricated to precise specifications, ensuring a snug fit and minimizing downtime caused by faulty components.

By utilizing custom parts manufacturing, companies can streamline their production processes and reduce interruptions and delays.

In addition to improved precision and efficiency, custom fabrication services offer a myriad of benefits.

Companies have the flexibility to customize their components to meet specific requirements, whether it’s selecting materials, finishes, or dimensions. This customization aligns perfectly with their production needs and preferences.

To ensure high-quality components, companies need to partner with reliable custom parts manufacturers. These manufacturers should have expertise and experience in designing, prototyping, and fabricating custom parts using advanced technology and machinery.

By choosing the right custom parts manufacturer, companies can guarantee the production of top-notch components that meet the highest standards of quality and performance. The collaborative efforts of custom parts manufacturers and the advancements in manufacturing parts assembly have revolutionized the industry.

| Benefits of Custom Parts Manufacturing | Advantages of Custom Fabrication Services | Importance of Reliable Custom Parts Manufacturers |

|---|---|---|

| Precision and Efficiency | Flexibility in Component Customization | Expertise in Designing and Fabrication |

| Reduced Downtime and Delays | Meeting Specific Requirements | Utilization of Advanced Technology |

| Streamlined Production Processes | Materials, Finishes, and Dimensions Selection | Guarantee of High-Quality Components |

Key Benefits of Using Custom Parts

Custom parts offer a range of advantages when it comes to designing, engineering, prototyping, and testing manufactured parts. These components are specifically created to meet the unique requirements and specifications of a particular application, resulting in improved quality and enhanced performance.

By utilizing custom parts, companies can achieve optimal functionality and efficiency, ensuring superior performance and longevity.

In addition, these parts provide flexibility and adaptability, allowing for easy incorporation of design changes or modifications.

This gives businesses a competitive edge by offering unique features or capabilities, leading to increased customer satisfaction. With the cost-effectiveness and competitive advantage that custom parts bring, it’s clear why they are the preferred choice in various industries.

Cost Savings through Custom Manufacturing

Cost savings through custom manufacturing extend beyond the initial design and engineering phase of creating custom parts and include quality control, inspection, and packaging of the manufactured parts. The manufacturing process itself offers several opportunities for reducing costs through efficient production methods and quality control.

Companies can implement rigorous testing and inspection procedures for each component, ensuring only high-quality parts are used in the final product.

This eliminates the need for expensive rework or replacements due to subpar parts.

Additionally, custom manufacturing allows for efficient packaging of the components, reducing the risk of damage during transportation and lowering packaging costs. Taking a holistic approach to cost savings, businesses can benefit from custom manufacturing in both the short and long term.

KLD Pumps offers superior parts and pricing for leading brands such as Wilfley, Krogh, Duro, and Flowserve, ensuring high-quality components at competitive prices.

Benefits of Custom Manufacturing

- Efficient production methods in custom manufacturing can lead to significant cost savings.

- Rigorous testing and inspection procedures ensure the use of high-quality parts in the final product, eliminating the need for expensive rework or replacements.

- Custom manufacturing allows for efficient packaging of components, reducing the risk of damage during transportation and lowering packaging costs.

- Taking a holistic approach to cost savings, businesses can benefit from custom manufacturing in both the short and long term.

Latest Trends in Parts Design and Engineering

In the ever-evolving field of parts design and engineering, staying up-to-date with the latest trends in manufacturing parts pricing is crucial. One trend that is gaining significance is the rise of additive manufacturing, also known as 3D printing.

This revolutionary technology allows engineers to create intricate and complex parts with unparalleled precision and efficiency. 3D printing offers endless possibilities, as it enables the production of parts that were previously either impossible or prohibitively expensive to manufacture.

The applications of 3D printing range from rapid prototyping to on-demand manufacturing, completely transforming the approach to parts design and production.

Ensuring Timely Delivery of Custom Parts

In the competitive world of manufacturing, ensuring the timely delivery of custom parts is essential for maintaining a competitive edge, especially considering the manufacturing parts production time required for each custom parts order. Meeting deadlines not only meets customer expectations but also helps establish a strong reputation in the market.

To achieve this, manufacturers need to prioritize effective communication, meticulous planning, collaboration with trusted suppliers, efficient production processes, and a contingency plan.

At KLD Pumps, we understand the importance of timely delivery, which is why we are committed to providing superior parts and pricing for various brands such as Wilfley, Krogh, Duro, and Flowserve.

Our extensive range of custom parts combined with our efficient manufacturing process ensures that orders are completed on time, minimizing delays and providing a seamless experience for our customers. With a focus on managing costs, providing accurate quotes, and streamlining production time, we strive to reduce manufacturing parts production time.

Timely Delivery in Manufacturing

- Effective communication ensures a clear understanding of customer requirements and reduces the chances of delays.

- Meticulous planning helps in identifying potential bottlenecks and streamlining the production process.

- Collaboration with trusted suppliers ensures reliable and timely delivery of required parts.

- An efficient production process minimizes lead times and increases the chances of meeting deadlines.