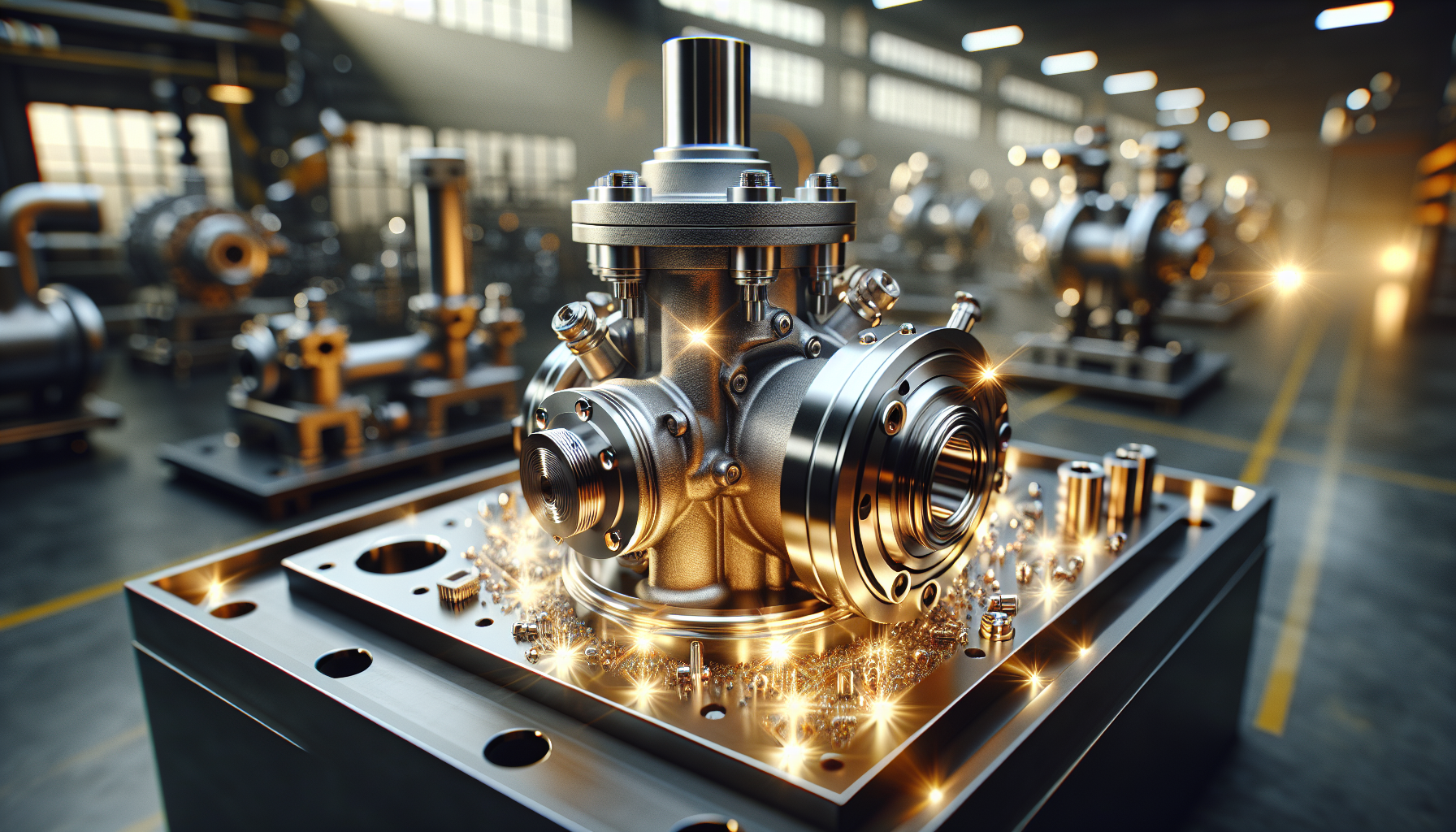

When it comes to custom pump parts, KLD pumps offer a wide range of pump components and pump accessories.com is the go-to source for superior quality and unmatched performance. Our specialized components are meticulously engineered using high-grade materials and precision manufacturing techniques.

This ensures durability, strength, and resistance to wear and tear.

Our custom pump parts also offer unparalleled performance, optimizing pump efficiency and output.

Whether you need to improve flow rates, reduce energy consumption, or enhance reliability, our parts deliver superior results. What sets us apart is our ability to customize these parts to suit specific pump models, applications, and industry needs.

With KLDpumps.com, you can expect top-notch quality, performance, and versatility that meet and exceed industry standards. Plus, our competitive pricing for Wilfley, Krogh, Duro, and Flowserve parts makes us the ideal choice for all your pump component needs.

Click here to learn more about kldpumps.com

Essential Components of a Pump

The fluid is directed in the desired direction with the help of pump impellers. The housing, on the other hand, provides support and stability for the entire pump assembly.

Another essential component to consider is the pump shaft.

This shaft connects the impeller to the motor, allowing for the transfer of power and rotation.

It needs to be durable and able to withstand the forces exerted during the pumping process.

The bearings of a pump are crucial for its smooth operation.

They reduce friction and allow for the rotation of the impeller and shaft. Proper lubrication of the bearings is essential to prevent premature wear and ensure the longevity of the pump.

When it comes to the maintenance and repair of pumps, it is important to have access to high-quality aftermarket pump parts. These parts, such as custom pump parts and pump seals, pump impellers, pump casings, pump housings, and pump gaskets, are crucial for ensuring the smooth operation of the machinery.

Choosing the Right Pump Fittings

The selection of pump fittings, such as pump bearings and pump shafts, plays a crucial role in ensuring the smooth and reliable operation of your pump system. It is important to consider the compatibility of the fittings with your specific pump to maximize efficiency.

Pump fittings, such as diaphragms, pistons, cylinders, bearings, and shafts, each serve a unique function and contribute to the overall performance and lifespan of the pump.

The choice of material for these fittings greatly affects their durability and resistance to corrosion.

With a wide range of options available, it is vital to select the appropriate pump fittings that meet your system’s specific requirements. For top-quality pump parts at competitive prices, visit KLDpumps.com, where you can find superior parts for well-known brands like Wilfley, Krogh, Duro, and Flowserve.

Facts About Pump Fittings

- Pump fittings, such as diaphragms, pistons, cylinders, bearings, and shafts, are essential components that contribute to the smooth and reliable operation of a pump system.

- The compatibility of pump fittings with a specific pump is crucial for maximizing efficiency and performance.

- The choice of material for pump fittings greatly impacts their durability and resistance to corrosion.

- By selecting appropriate pump fittings that meet the system’s specific requirements, the overall lifespan of the pump can be extended.

The Importance of Pump Seals in Leak Prevention

Pump seals, along with pump flanges, pump filters, pump strainers, pump connectors, and pump couplings, are essential components of any pumping system as they play a crucial role in preventing leaks and maintaining efficiency. These seals create a tight barrier between the rotating shaft of the pump and the stationary housing, effectively stopping any fluid or gas from leaking.

The significance of pump seals lies in their ability to prevent environmental pollution, which is one of the key reasons why they are so important.

Leaks from pumps can result in the release of hazardous substances into the environment, causing damage to ecosystems and posing health risks.

By effectively sealing the pump, these risks can be minimized, ensuring a safer and cleaner environment.

Pump seals also contribute to energy conservation.

When a pump is leaky, valuable fluids or gases can be lost, leading to increased energy consumption. By maintaining a tight seal, pump seals help prevent such leaks, ultimately improving the overall energy efficiency and reliability of pump couplings.

Enhancing Pump Performance with High-Quality Impellers

Investing in high-quality pump impellers is essential for enhancing pump performance and can be complemented by other components such as pump plates or pump covers. These impellers are meticulously designed and manufactured to optimize efficiency and performance.

Made of materials like stainless steel, bronze, or cast iron, they offer excellent resistance to corrosion, erosion, and wear, resulting in a longer lifespan.

High-quality impellers have precision engineering and tight tolerances, which reduce vibration and noise levels.

Their hydraulic performance is optimized to meet specific pump system requirements, leading to improved flow rates and higher head pressures.

KLDpumps. com offers superior parts and competitive pricing for Wilfley, Krogh, Duro, and Flowserve parts

Benefits of Investing in High-Quality Pump Impellers

- Enhanced pump performance and efficiency

- Resistance to corrosion, erosion, and wear, leading to a longer lifespan

- Reduced vibration and noise levels due to precision engineering and tight tolerances

- Optimized hydraulic performance to meet specific pump system requirements, resulting in improved flow rates and higher head pressures

Exploring Different Types of Pump Casings and Their Functions

When exploring various types of pump casings and their functions, it is essential to understand how the design of pump plungers affects performance. The efficiency and effectiveness of a pump casing in fluid pumping are directly impacted by its design.

The shape, size, and material of the casing all contribute to its performance.

The design must consider factors such as flow rate, pressure requirements, and the nature of the fluid being pumped.

By careful consideration of these aspects, one can optimize the pump system and ensure seamless operation

Understanding the Role of Pump Housings in Maintaining Integrity

Pump housings, along with pump bolts and pump screws, are crucial components in maintaining the integrity and efficiency of pump systems. These housings not only provide physical protection to internal components but also serve as a barrier against noise and vibration, ensuring smooth and quiet operation.

Manufacturers often incorporate specialized designs in these housings to optimize heat dissipation, preventing overheating and extending the lifespan of the pump.

Accessible designs make routine maintenance and repair tasks easier.

At KLD Pumps, we offer superior parts and pricing for renowned pump brands like Wilfley, Krogh, Duro, and Flowserve. Visit our website to learn more about our high-quality products.

Facts About Pump Housings

- Pump housings protect internal components from physical damage.

- Specialized designs in pump housings optimize heat dissipation, preventing overheating.

- Housings serve as a barrier against noise and vibration, ensuring smooth and quiet operation.

- Accessible designs in pump housings make routine maintenance and repair tasks easier.

Significance of Pump Gaskets in Ensuring a Tight Seal

When it comes to maintaining a tight seal in pump applications, pump gaskets, along with pump clamps and pump brackets, play a crucial role. These small yet essential components are designed to prevent leakage and uphold the integrity of the system.

Pump gaskets are known for their ability to withstand high pressures and temperatures, thanks to their durable materials such as rubber, silicone, or metal.

Their flexibility allows them to conform to the irregularities and imperfections of mating surfaces, ensuring a reliable seal.

Moreover, pump gaskets are instrumental in preventing contamination, ensuring the purity of fluids being pumped. In industries like pharmaceuticals, food processing, and chemical manufacturing, maintaining product integrity is of utmost importance, making pump gaskets indispensable.

Selecting the Right Pump Diaphragm for Your Application

Selecting the right pump diaphragm, along with the appropriate pump springs and pump plugs, is crucial to ensure optimal performance and longevity. It is important to choose diaphragms made from durable materials that have been tested for their longevity in similar operating conditions.

The size and shape of the diaphragm should fit properly within the pump chamber to ensure proper sealing and efficient operation.

When sourcing pump diaphragms, it is beneficial to consider OEM options as they are specifically designed and manufactured for particular pump models.

OEM diaphragms provide a higher level of compatibility and reliability compared to aftermarket or generic pump parts.

Consulting with pump manufacturers or experts is highly recommended to determine the most suitable diaphragm for your specific application.

They can provide valuable insights and guidance based on their knowledge and experience in the industry. Selecting the right pump caps can ensure efficient performance and reliable operation.

Selecting Pump Diaphragms

- Choosing diaphragms made from durable materials ensures longevity in similar operating conditions.

- The size and shape of the diaphragm should fit properly within the pump chamber for proper sealing and efficient operation.

- OEM diaphragms provide a higher level of compatibility and reliability compared to aftermarket or generic pump parts.

- Consulting with pump manufacturers or experts can provide valuable insights and guidance based on industry knowledge and experience.

Upgrade Your Pump Performance with Top Quality Accessories

Upgrading Your Aftermarket Pump Components