Introduction to Industrial Parts Investment

Investing in industrial parts presents a lucrative opportunity for those aiming to diversify their investment portfolio and capitalize on the growing machinery parts market. These essential components are in high demand across diverse industries such as manufacturing, construction, and automotive, making them a wise choice for steady returns. To maximize profitability, conducting thorough research into industries dependent on these parts and evaluating their growth potential is crucial.

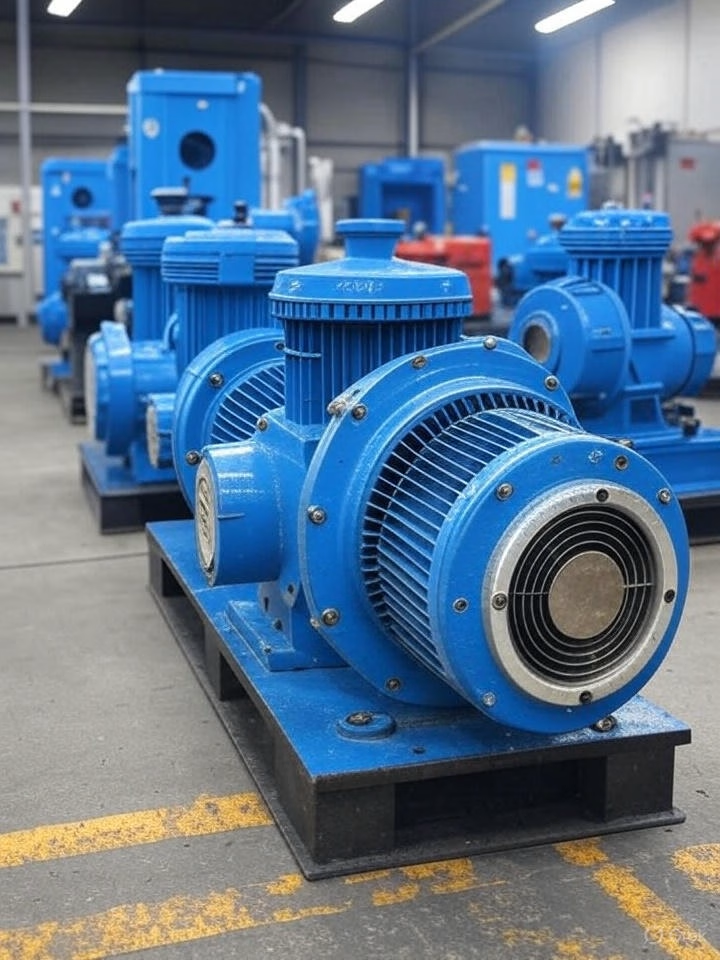

Selecting reputable manufacturers or suppliers is vital to ensure you acquire high-quality parts with extended lifespans, thereby reducing the risk of expensive repairs or replacements. Staying informed about technological advancements and industry innovations can further enhance your investment strategy. For top-tier parts and competitive pricing for brands like Wilfley, Krogh, Duro, and Flowserve, explore KLD Pumps. Click here to learn more about their offerings.

How to Choose the Right Industrial Equipment

Choosing the appropriate industrial machinery is a pivotal decision that can significantly influence your business’s success. It’s essential to assess your specific needs and requirements, considering factors such as the equipment’s intended tasks and performance expectations. Prioritize quality and reliability by partnering with reputable manufacturers and suppliers who provide durable equipment.

Safety features are paramount in industrial settings, so opt for machinery that adheres to safety standards. Additionally, ensure the availability of spare parts and robust after-sales support to minimize downtime and extend equipment longevity. Visit KLD Pumps for reliable solutions tailored to your needs.

The Importance of Regular Maintenance for Machinery

Regular maintenance is indispensable for ensuring the longevity and optimal performance of industrial machinery, particularly its parts. Neglecting maintenance can lead to costly breakdowns, reduced productivity, and safety risks. To avert major issues, conduct routine inspections, lubricate components, and replace worn-out parts promptly.

Adhering to a consistent maintenance schedule can significantly prolong your machinery’s lifespan. Beyond preventing unexpected failures, regular maintenance boosts uninterrupted production, enhances customer satisfaction, and delivers cost savings. It also improves machinery performance, reducing energy consumption, enhancing product quality, and ensuring compliance with industry regulations. For superior parts and pricing for Wilfley pumps, trust KLD Pumps.

Benefits of Regular Machine Maintenance

- Prevents breakdowns and costly repairs.

- Increases productivity and efficiency.

- Improves product quality and customer satisfaction.

- Ensures compliance with industry regulations and standards.

Key Components to Consider in Equipment Investment

When investing in industrial equipment, businesses must evaluate several key components, including machine replacement parts, to make informed choices. Assess your industry’s specific needs and identify the types of equipment parts required. Understanding your production process and pinpointing inefficiencies that new equipment can address is equally important.

Evaluate the quality and reliability of the equipment to lower maintenance costs and downtime. Consider the availability of spare parts and technical support, which are critical for efficiency and longevity. Factors like cost, compatibility, and future growth potential should also guide your decision-making process for a profitable investment. Check KLD Pumps for high-quality options.

Upgrading Your Manufacturing Machinery

Staying abreast of the latest advancements in industrial machine parts is essential when upgrading your manufacturing machinery. Knowledge of available technologies enables informed decisions about upgrades that align with your manufacturing needs. Ensure the availability of compatible industrial parts to prevent production delays and minimize downtime during upgrades.

Investing in machinery upgrades can lead to enhanced productivity, cost savings, and a competitive edge in the manufacturing sector. For a wide range of superior parts at competitive prices for Wilfley, Krogh, Duro, Flowserve, and more, visit KLD Pumps.

Benefits of Upgrading Manufacturing Machinery

- Improved efficiency and productivity through faster processes and higher output.

- Cost savings from reduced energy use and waste with advanced technologies.

- Enhanced product quality with greater precision and reliability.

- Competitive advantage by meeting customer demands with cutting-edge solutions.

The Role of Spare Parts in Industrial Operations

Spare parts are vital in industrial operations, preventing production disruptions from equipment breakdowns and enabling efficient repairs. They serve as a safety net, minimizing downtime and maximizing productivity. A well-organized inventory management system is key to accessing necessary spare parts quickly.

Quality is as important as availability; investing in high-quality components reduces the frequency of breakdowns and enhances performance. Regular maintenance and inspections optimize spare part usage by addressing potential issues early. Prioritizing availability, quality, and maintenance ensures uninterrupted operations. Explore KLD Pumps for reliable spare parts.

Maximizing ROI with Effective Parts Investment

Maximizing return on investment (ROI) through effective parts investment involves considering the impact of industrial machinery components on maintenance and refurbishment. High-quality industrial parts ensure machinery longevity and optimal performance. Prioritizing repairs and regular maintenance reduces downtime, boosting ROI.

Businesses should refine their parts investment strategy, focusing on reliable components. At KLD Pumps, we offer a broad selection of dependable industrial machinery components for Wilfley, Krogh, Duro, and Flowserve, designed to enhance performance and durability, supporting efficient maintenance, refurbishment, and repairs.

Industrial Machinery Components

- High-quality parts ensure longevity and optimal performance.

- Regular maintenance and repairs reduce downtime, improving ROI.

- Reliable components enhance equipment durability.

- Efficient maintenance and refurbishment lead to cost savings and productivity gains.

Best Practices for Industrial Equipment Repairs

Regular equipment upgrades and machine component maintenance are crucial for optimal performance and minimal downtime in industrial settings. Proactively assessing and investing in upgrades extends the lifespan of manufacturing machinery, protecting your investment. Addressing repair needs promptly prevents costly breakdowns and ensures smooth operations.

Prioritizing upgrades and using high-quality replacement parts further improves performance and maximizes equipment investment returns. Visit KLD Pumps for top-quality replacement parts.

Improving Efficiency and Productivity with Machinery Upgrades

Upgrading machinery is a strategic step to enhance efficiency and productivity across industries, particularly through equipment refurbishment and component upgrades. The right upgrades optimize operations, reduce downtime, and increase output. Ensuring compatibility with readily available parts, such as those from KLD Pumps, is critical.

KLD Pumps provides superior parts and pricing for leading brands like Wilfley, Krogh, Duro, and Flowserve, improving machinery reliability and performance. Partnering with KLD Pumps reduces maintenance costs, maximizes uptime, and supports effective maintenance and refurbishment.

Industrial Parts Provider Benefits

- KLD Pumps: Offers superior parts and pricing for leading pump brands.

- Compatibility with readily available parts: Ensures smooth business operations.

- Reduces maintenance costs: Maximizes uptime.

Conclusion: Invest in Industrial Parts to Boost Your Profits

Investing in industrial parts not only diversifies your portfolio but also boosts profits by meeting the demands of key industries. With strategic research, quality sourcing, and regular maintenance, you can achieve significant returns. Discover how KLD Pumps can support your investment goals with high-quality parts and competitive pricing.

Tags: industrial parts, machinery investment, KLD Pumps, equipment maintenance, manufacturing upgrades

Categories: Industrial Equipment, Machinery Investment