Aftermarket Krogh Carver 855 Series Pump Parts by KLD Pumps

Welcome to KLD Pumps’ premier resource for Krogh Carver 855 Series pump parts. At KLD Pumps, we deliver high-performance aftermarket parts for the Krogh Carver 855—a vertical vacuum filtrate pump engineered in the 1950s for OEM vacuum filtration systems, now a cornerstone of Carver Pump’s legacy (source). Designed for rugged industrial applications like chemical processing, mining, wastewater treatment, and power generation, the 855 Series excels under vacuum conditions up to 26″ Hg and flows up to 700 GPM. Rooted in Southeastern Idaho’s phosphoric acid industry, KLD Pumps leverages over 100 years of collective expertise to provide in-stock and custom parts that outlast and outperform OEM standards, ensuring reliability, durability, and cost savings. Explore our homepage or aftermarket parts catalog for more.

Why Choose KLD Pumps for Krogh Carver 855 Series Parts?

KLD Pumps is your trusted partner for maintaining and enhancing the Krogh Carver 855 Series:

- Unmatched Expertise: Over a century of experience in phosphoric acid and abrasive environments, delivering parts with tolerances as tight as ±0.001 inches for critical mating surfaces like impeller-to-shaft fits.

- Superior Materials: CD4MCuN (UNS J93370, 25% Cr, 5% Ni, PREN > 40) and Duplex Stainless Steel (ASTM A890 Grade 5A) offer yield strengths up to 100 ksi and corrosion resistance in pH 2-4 fluids—perfect for harsh slurries and acids.

- Advanced Customization: 3D-scanned parts with 0.005-inch accuracy optimize legacy 855 models, reducing NPSHr by up to 10% and improving flow dynamics.

- Reliable Supply Chain: In-stock 855 parts (e.g., impellers, seals) ship immediately, with 24-hour quote responses and engineer-led support—see our homepage for details.

Krogh Carver 855 Series Overview

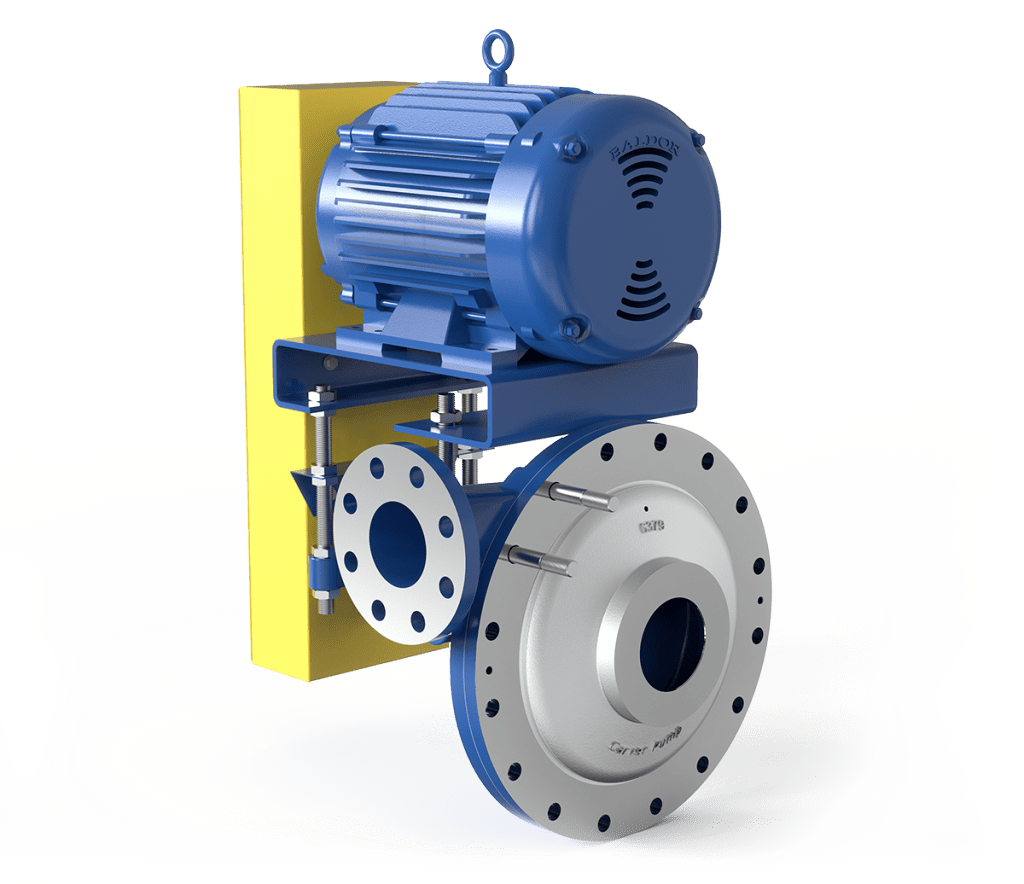

The Krogh Carver 855 Series is a vertical vacuum filtrate pump designed for direct tank mounting, eliminating suction piping and minimizing NPSH challenges. Developed in the 1950s, it features a semi-open impeller, overhead V-belt drive (optional close-coupled 855-CC), and a vertically-split casing for easy maintenance. Available in six sizes (1″ to 4″ discharge), it supports diverse applications with materials like All Iron, CD4MCuN, and Rubber Lined options.

| Specification | Details |

|---|---|

| Max Vacuum | 26″ Hg |

| Max Flow | 700 GPM (159 m³/hr) |

| Max Head | 120 ft (36.6 m) |

| Max Power | 20 HP (14.9 kW) |

| Max Speed | 2,450 RPM |

| Max Temperature | 250°F (121°C) |

| Discharge Sizes | 1″ to 4″ (25.4 to 101.6 mm) |

| Materials | All Iron, CD4MCuN, Rubber Lined |

Available Krogh Carver 855 Series Parts

KLD Pumps offers a full suite of aftermarket Krogh Carver 855 parts, engineered for peak performance in abrasive, corrosive, and high-vacuum conditions. Below is a detailed breakdown:

Impellers

Description: Semi-open, precision-balanced, available in CD4MCuN, All Iron, or Rubber Lined.

Technical Specs: Handles 700 GPM at 26″ Hg, keyed to shaft for reverse rotation protection.

Benefits: Up to 85% hydraulic efficiency, resists pitting in 20,000 ppm Cl⁻ fluids.

Applications: Vacuum filtration, mining slurries, chemical processing.

KLD Edge: In-stock, optimized via 3D scanning for legacy fitment.

Shafts

Description: Duplex SS (17-4PH or ASTM A890 Grade 5A), no sleeve needed, stress-relieved.

Technical Specs: Max deflection <0.002 in/ft, supports 2,450 RPM.

Benefits: Alignment within 0.001 TIR, withstands 5,000 ft-lb torque.

Applications: High-torque condensate systems in power generation.

KLD Edge: Custom lengths, in-stock for immediate delivery.

Casings

Description: Vertically-split, direct tank-mounted, in All Iron, CD4MCuN, or Rubber Lined.

Technical Specs: Exposes wetted areas for maintenance, supports 120 ft head.

Benefits: Eliminates suction piping, reduces NPSH issues.

Applications: Wastewater sludge dewatering, chemical filtration.

KLD Edge: 3D-scanned for exact fit, optional swing-out mount compatibility.

Stuffing Box & Seals

Description: Packed stuffing box with seal water, optional SiC/SiC mechanical seals.

Technical Specs: 2” bore, 350 psig, vacuum to 26″ Hg.

Benefits: Leakage <0.1 oz/hr, maintains vacuum integrity.

Applications: Phosphoric acid handling, corrosive fluids.

KLD Edge: API 682-compliant options, in-stock packing kits.

Bearings

Description: Grease-lubricated ball bearings for overhead V-belt models.

Technical Specs: 15,000 lbf radial load, <0.15 ips RMS vibration.

Benefits: Smooth operation at 2,450 RPM, 20-month MTBF.

Applications: Heavy-duty mining, power generation.

KLD Edge: ISO 281-rated, in-stock replacements.

Discharge Flanges

Description: Machined for Class 150 ANSI and DIN PN10 connections.

Technical Specs: 1″ to 4″ sizes, 150 psig pressure rating.

Benefits: Universal fit, corrosion-resistant options.

Applications: Industrial piping in chemical plants.

KLD Edge: Precision-machined, optional coatings.

Wear Rings

Description: High-chrome iron (>600 BHN) or CD4MCuN, optional for 855.

Technical Specs: Reduces internal leakage, fits semi-open impeller.

Benefits: 40% less wear in slurries, extends MTBR by 6-12 months.

Applications: Mining slurries, abrasive fluids.

KLD Edge: Custom-fit, in-stock for select sizes.

In Stock: Impellers, shafts, seals, bearings, and more—ready to ship! Contact us at kldpumps.com.

Applications of the Krogh Carver 855 Series

The 855 Series is a proven performer in:

- Chemical Processing: Vacuum filtration of pH 2-4 fluids, e.g., phosphoric acid production.

- Mining: Slurry handling (30% solids) in ore processing.

- Wastewater Treatment: Sludge dewatering under vacuum conditions.

- Power Generation: Condensate management in boiler systems.

OEM vs. KLD Aftermarket Parts

| Feature | KLD Aftermarket | OEM |

|---|---|---|

| Cost | 20-30% less, same quality | Higher due to branding |

| Lead Time | In-stock, 2-4 weeks for custom | 6-8 weeks |

| Materials | CD4MCuN (PREN > 40), Duplex SS | Standard alloys |

| Customization | 3D scanning for upgrades | Limited options |

| Support | Engineer-led, 24-hr quotes | Generic, slower |

Case Study: A mining operation cut downtime by 40% (12 to 7 days/year) with KLD’s in-stock CD4MCuN impeller, saving $35,000 annually.

How to Order Krogh Carver 855 Parts

- Identify your 855 model (e.g., 855-OH, 855-CC) and conditions (flow, vacuum, fluid type).

- Contact us via kldpumps.com with serial number.

- Receive a detailed quote within 24 hours; in-stock parts ship same day.

- Install and optimize your 855’s performance.

Order today at kldpumps.com.

FAQs

- Compatibility? Yes, fits all 855 variants, including legacy models.

- Warranty? 1-year against defects.

- Lead Time? In-stock parts ship immediately; custom parts 2-4 weeks.

- Custom Options? Available via 3D scanning for unique needs.

Resources for 855 Series Owners

- Maintenance Tips: Check seals every 1,000 hours, maintain wear ring clearance at 0.010-0.015 inches.

- Technical Guide: Coming soon—detailed 855 part fitment and specs.

- Case Study: Power plant increased MTBF from 10 to 24 months with KLD’s Duplex SS shaft.

For more, visit kldpumps.com.