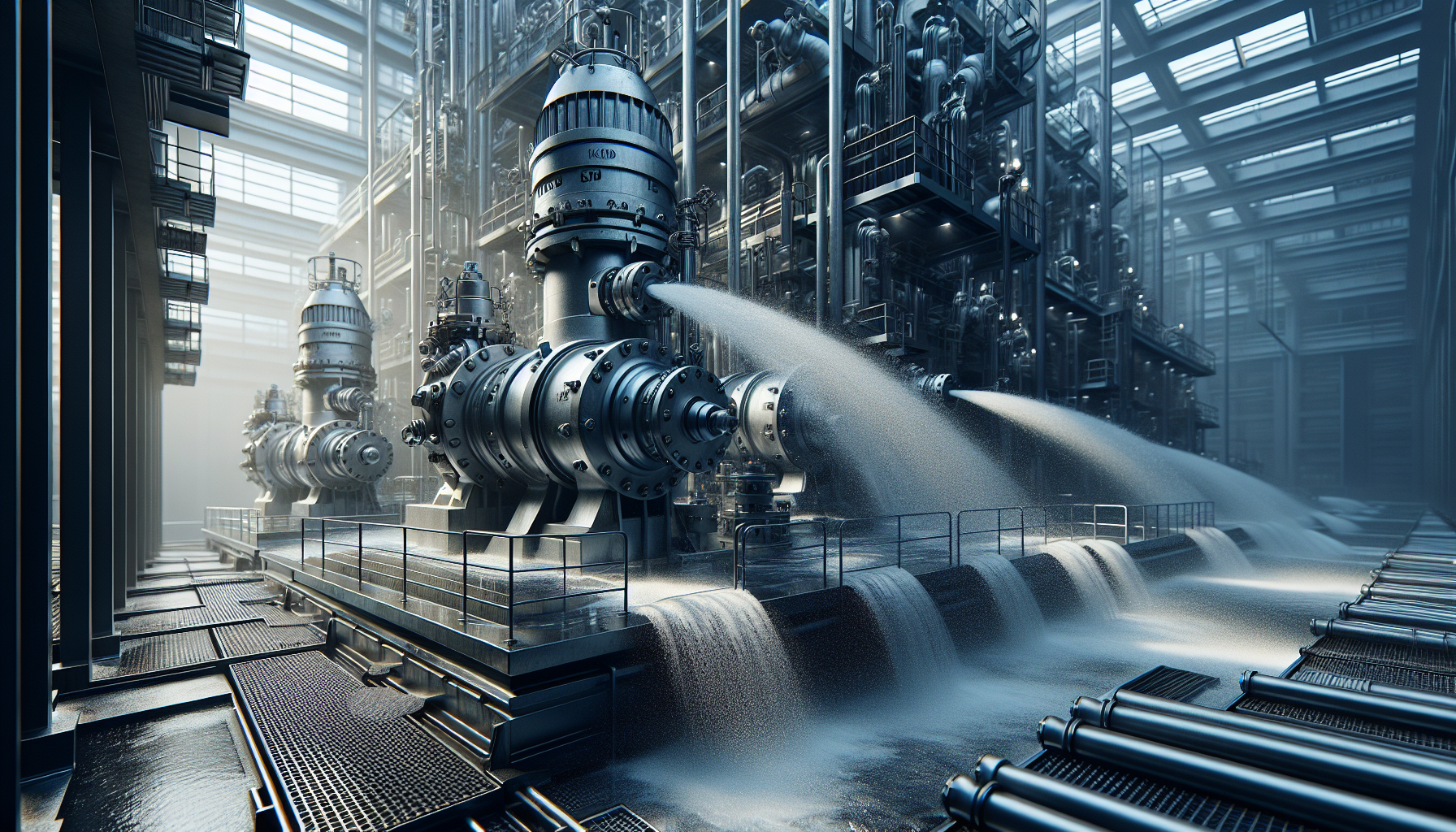

KLD pumps are revolutionizing industrial applications with their powerful performance and enhanced efficiency, especially in the realm of submersible pumps. These pumps excel at delivering exceptional flow rates and generating substantial pressure, making them perfect for challenging tasks.

Whether it’s pumping large volumes of water or handling corrosive fluids, KLD pumps effortlessly tackle any job.

But it’s not just about power – KLD pumps offer exceptional efficiency, resulting in significant cost savings for businesses.

By minimizing energy consumption, these pumps not only contribute to a reduced environmental impact but also maximize operational savings.

KLD pumps are engineered to withstand the harshest operating conditions, ensuring uninterrupted performance in demanding environments.

Their durability and reliability make them the go-to choice. For superior parts and pricing on well-known brands like Wilfley, Krogh, Duro, and Flowserve, visit KLDp, your go-to source for a wide range of industrial pumps including water pumps, submersible pumps, centrifugal pumps, and hydraulic pumps.

Click here to learn more about: kldpumps.com

How Submersible Pumps Work

Electric pumps and well pumps can function in depths of up to 500 feet, while vacuum pumps and sump pumps are capable of operating in depths of up to 3,000 feet. This makes them suitable for a wide range of applications, including industrial pumping, wastewater management, groundwater extraction, and oil drilling.

KLD Pumps, a leading manufacturer in the industry, offers a diverse range of submersible pumps that cater to different needs and requirements.

Their line of industrial pumps is highly sought after for their reliability, durability, and efficiency. KLD’s centrifugal pumps are renowned for their efficiency and reliability in various applications, including electric pumps, sewage pumps, sump pumps, diaphragm pumps, vacuum pumps, well pumps, fuel pumps, and air pumps.

Benefits of Industrial Pumps

Industrial pumps are essential for various industries, and KLD Pumps is leading the way in providing high-quality centrifugal pumps, including booster pumps, irrigation pumps, chemical pumps, gear pumps, piston pumps, positive displacement pumps, fire pumps, and slurry pumps. These pumps are not only efficient but also versatile and durable.

When it comes to efficiency, KLD Pumps stand out from the competition.

They are designed using advanced technology and engineering, maximizing energy efficiency while minimizing wastage.

This translates to significant cost savings for businesses and a reduced carbon footprint.

In terms of versatility, KLD Pumps can handle a wide range of substances, including corrosive chemicals, abrasive slurries, and viscous liquids.

These pumps can be customized to meet the specific needs and requirements of different industries.

The durability of KLD Pumps is exceptional.

Constructed with robust materials, they are built to withstand demanding industrial environments. To learn more about KLD Pumps and their superior parts and pricing for popular brands like Wilfley, Krogh, explore their wide range of pumps including booster pumps, irrigation pumps, chemical pumps, gear pumps, piston pumps, positive displacement pumps, fire pumps, and slurry pumps.

| Pump Type | Efficiency | Versatility | Durability |

|---|---|---|---|

| Booster Pumps | Maximizing energy efficiency | Can handle various substances | Constructed with robust materials |

| Irrigation Pumps | Minimizing wastage | Customizable for different industries | Built to withstand demanding environments |

| Chemical Pumps | Significant cost savings | Capable of handling corrosive chemicals | Exceptional durability |

| Gear Pumps | Reduced carbon footprint | Can handle abrasive slurries | |

| Piston Pumps | Capable of handling viscous liquids | ||

Suitability of Centrifugal Pumps for High-Pressure Applications

Centrifugal pumps are efficient and versatile machines that are highly suitable for high-pressure applications such as circulating pumps or oil pumps. These pumps are commonly utilized in various industries because they can handle large flow rates and move fluid at high speeds.

Due to their compact size and easy installation, centrifugal pumps can be conveniently placed in tight spaces or on mobile equipment.

Their excellent energy efficiency allows them to handle the required high pressures without consuming excessive power.

Maintenance for centrifugal pumps is also relatively easy, making them a cost-effective option for high-pressure applications.

Importance of Hydraulic Pumps in Heavy Machinery

Hydraulic pumps play a crucial role in heavy machinery, providing numerous advantages that make them indispensable across industries, including agricultural pumps, submersible well pumps, and electric water pumps. One notable example is KLD Pumps, widely used in various sectors, including agriculture, to ensure efficient irrigation and water supply for crops.

Industrial pumps, such as centrifugal pumps, are essential for pond maintenance, as they help circulate and oxygenate water, supporting aquatic life.

Submersible well pumps are also vital for accessing clean water from underground sources.

The versatility and significance of hydraulic pumps in meeting the specific requirements of heavy machinery in diverse sectors are evident. To learn more about reliable hydraulic pump parts and competitive pricing, visit KLDpumps.com

| Types of Hydraulic Pumps | Advantages |

|---|---|

| Agricultural Pumps | Ensure efficient irrigation and water supply for crops |

| Submersible Well Pumps | Access clean water from underground sources |

| Electric Water Pumps | Provide reliable water supply in various industries |

| Centrifugal Pumps | Essential for pond maintenance, circulating and oxygenating water |